From Factory to Kitchen: The CLOSER FINEMIX Emulsification Experience

[Summary]

The technology of emulsification may not be familiar to many of us, but it is actually used in many products around us, creating numerous functions. It is now essential for the production of these products and is a technology that holds many possibilities for the future. However, the emulsification process in current product manufacturing mostly relies on emulsifiers. Moving away from emulsifiers to a more natural and healthy method of emulsification is a new challenge in today's food science.

Our compact emulsification device, "CLOSER FINEMIX," embodies this challenge and is designed to easily perform emulsification at home. This article presents the development philosophy behind CLOSER and its capabilities, with a focus on new possibilities in culinary applications for chocolate, presented in the form of a presentation.

[Presentation video]

[Main Text]

Hello everyone, this is the Emulsification Lab at OKUTEC Corporation.

Have you ever heard of an "emulsification device"? You may have heard the term emulsification, but most likely not the device. And it's even less likely that you have used an emulsification device for cooking at home. But what if there was an emulsification device that was easy to use and close at hand? That's our topic for today. Please join us in considering the future of emulsification with "CLOSER FINEMIX."

1.What is emulsification?

Firstly, emulsification is the process of mixing substances that do not naturally blend, like water and oil, with the aim of combining completely different properties to create new characteristics and performance. For example, in lotions, it creates properties that neither water nor oil alone could provide, such as a "moist yet smooth" feel.

2.Various familiar products that utilize emulsification technology

Emulsification technology is used in many products that are part of our daily lives. With the diversification of petrochemical products, new products with novel functions and performance are being developed, and emulsification technology has spread to various fields, including cosmetics and food. Now, Let's take a look at the general manufacturing process of emulsification!

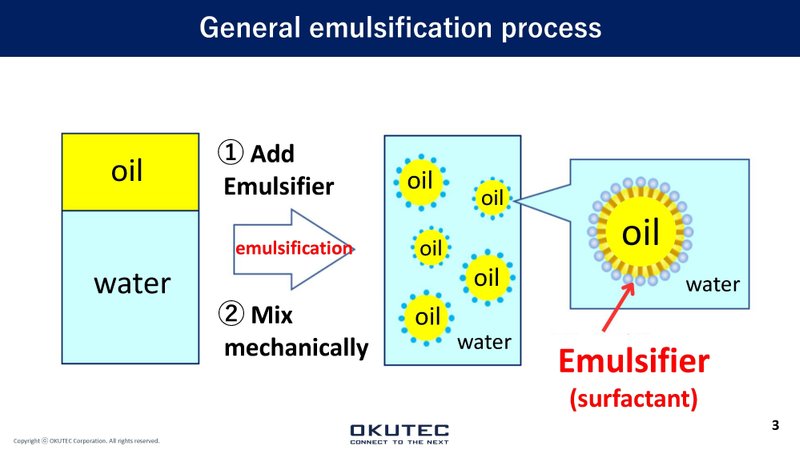

3.General emulsification process

When "water and oil" are placed in a container, they separate completely. However, by adding substances called emulsifiers or surfactants and mechanically mixing them, the water and oil mix well through the emulsifier and become emulsified. This mixing machine is called an emulsification device, and various types are used depending on the application. However, to maintain the emulsified state for several years, both additives such as emulsifiers and surfactants and the emulsification device are necessary. The device alone cannot create a stable emulsified state over a long period, which is a challenge.

4.Naked oil drop

The image on the left of this slide shows an enlarged view of particles emulsified using an emulsifier. For example, in lotion, the effective ingredient, oil, is completely covered by the emulsifier, meaning the effective ingredient does not directly touch the skin but rather the emulsifier does first. We are considering whether we can create "naked oil droplets" without using emulsifiers, as shown in the image on the right. Achieving natural and healthy emulsification without heating or additives, using only a device, is also a challenge in current food science. However, maintaining these "naked oil droplets" stably without separation over several years is not easy with the current level of technology. Therefore, we thought of a usage that does not require long-term storage. In other words, the idea is to emulsify at the place of consumption. For example, if there was a machine that could easily emulsify in homes or restaurants, new values and uses could be created. This led to the start of the "CLOSER" project, which aims to bring the emulsification device closer to the point of consumption.

5.Specification of CLOSER FINEMIX

And finally, after new technological developments, we have developed the cooking emulsification device "CLOSER FINEMIX." Its distinctive feature is that it does not have a rotating cutter like a mixer; it emulsifies solely with a jet of water from the nozzle.

6.Emulsification method of CLOSER FINEM

The emulsification principle of CLOSER is a patented technology that applies the ultrafine bubble generation technology popularized in showerhead TV commercials. It creates a high-speed vortex inside the nozzle to finely disperse water and oil, achieving miniaturization.

7.Emulsification experiments using chocolate

So far, we have talked about the development of CLOSER. Now, let's introduce what CLOSER can do, using chocolate as a specific example. First, let me introduce some experiments using chocolate.

8.Ingredients of dried cacao beans

Do you drink chocolate drinks? Have you ever felt grittiness or sediment when enjoying a chocolate drink? Depending on the product, high-cacao chocolate contains about 50% fat called cacao butter. The grittiness left in the drink is thought to be due to the liquid and cacao butter being water and oil, which naturally do not mix.

9.Cacao butter emulsification test

The first experiment was to dissolve cacao butter in hot water and compare the results of hand-mixing with a whisk and mixing with CLOSER. The photo on the left is probably easy for you to imagine; like dressing, no matter how hard you mix, it does not emulsify and separates immediately. However, the mixture with CLOSER is cloudy, showing that the liquid and fat have emulsified and become one.

10.Chocolate drink emulsification test

Next, we compared chocolate drinks. Even with the same ingredients, the color and grittiness are completely different between the drink mixed with a whisk and the one mixed with CLOSER. You can see the difference in grittiness at the edge of the cup. Also, the "flavor" and "texture" when drinking are completely different.

11.Microscope observation of chocolate drink

Furthermore, we observed the state of oil droplets in the chocolate drink under a microscope. The one mixed with a whisk hardly showed any "oil droplets" under the microscope, but the one emulsified with CLOSER confirmed that fine "oil droplets" were uniformly formed.

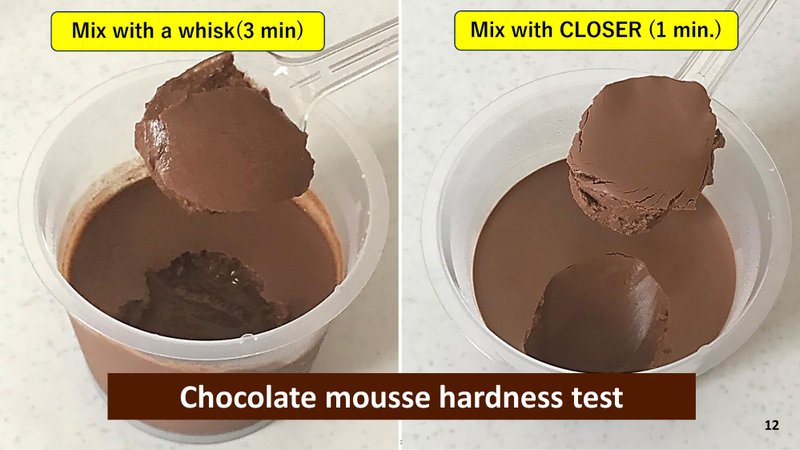

12.Chocolate mousse hardness test

The last test I will introduce is a comparison test to see how much a mixture of high-cacao chocolate and hot water in a 1:2 ratio solidifies after being chilled in the refrigerator overnight. A clear difference was confirmed. The one emulsified with CLOSER had no separation of water and became a complete mousse, while the one mixed vigorously by hand with a whisk only solidified on the surface, and the inside was like a sherbet. We believe these results expand the possibilities for chocolate cooking, not only for mousse but also for raw chocolate, chocolate sauce, terrine, and bonbon chocolates.

Now, let me summarize the features of CLOSER FINEMIX for chocolate applications into three points.

13.Features of CLOSER FINEMIX

First, it brings out the original deliciousness of cacao by naturally and healthily emulsifying flavor-packed cacao butter without additives or heat treatment.

Second, it allows for easy emulsification with the push of a button, achieving professional-quality texture effortlessly.

Third, it opens up possibilities for new menu development in various chocolate cooking applications beyond drinks, including mousse, truffles, sauces, and terrines.

14.Creating new uses and values.

Having an easy-to-use emulsification device close at hand means that the emulsification process used in manufacturers' factories can be performed in stores and homes without emulsifiers, creating new uses and values.

15.The future of natural and healthy emulsification

This time, we introduced the application of emulsification using chocolate as an example, but emulsification can also be utilized in various cooking applications such as drinks, sweets, dressings and sauces, broths, and soups. We hope you will join us in considering the future of natural and healthy emulsification.

Thank you for your attention

この記事が気に入ったらサポートをしてみませんか?