Plotclockが作りたくなりました。

前から興味があったPlotclockを作りたいと思います。材料は自宅に転がっていたArduinoUNO互換品とサーボモーターSG90(3個)を使用します。

側は中国の安っすいのを注文しました。例によっていつ来るかわからないので、配線とコードの方を進めていきます。検索すると、色々情報があって助かります。

まずは、Arduinoに、Timeのライブラリーを入れます。

まずはこちらのサイトから、Time-master.zipをダウンロードします。

https://github.com/PaulStoffregen/Time

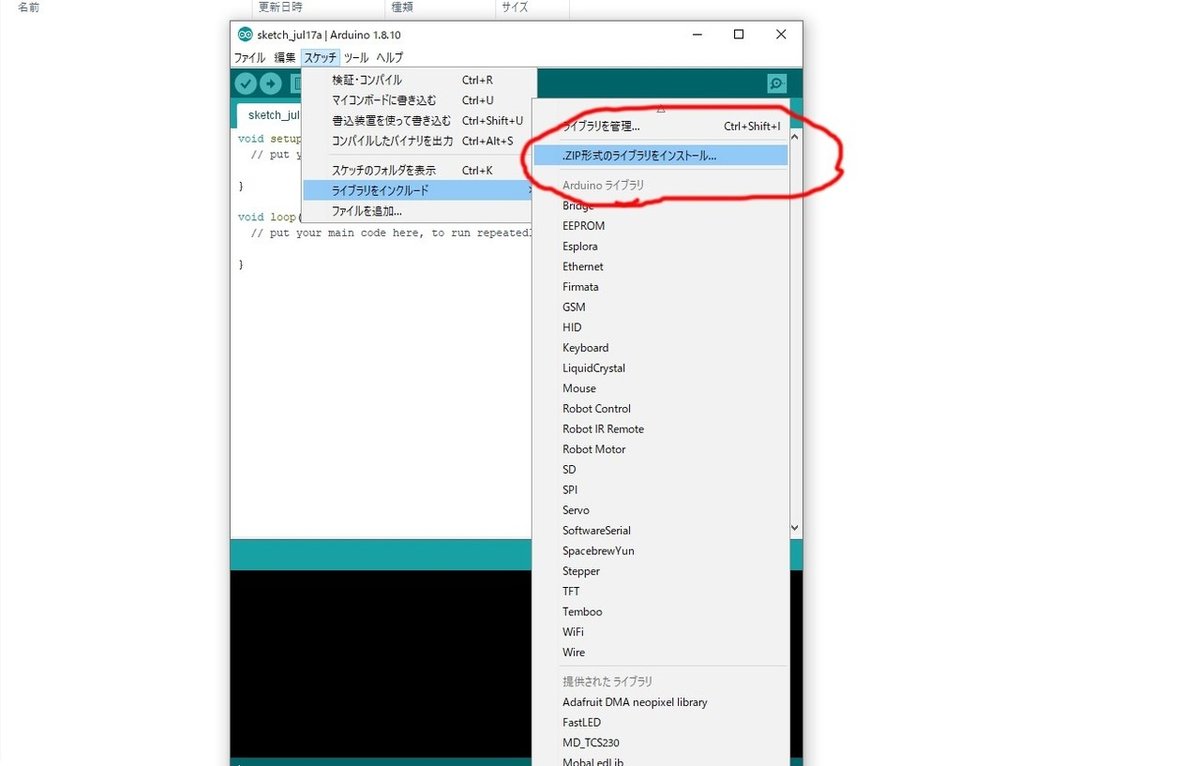

そしたら、ArduinoIDを開き、スケッチ→ライブラリをインクルード→zip形式のライブラリをインストール

するとライブラリの中に、Timeが現れます。

そしたらこれをインクルードします。するとこうなります。

次は、Plotclockのcodeを入れます。コードはこちらものをお借りしました。

https://www.thingiverse.com/thing:248009/files

こちらから、Arduinoのcodeをダウンロードして、Timeのライブリをインクルードします。そうすとこんなcodeになります。

#include <TimeLib.h>

// Plotclock

// cc - by Johannes Heberlein 2014

// v 1.02

// thingiverse.com/joo wiki.fablab-nuernberg.de

// units: mm; microseconds; radians

// origin: bottom left of drawing surface

// time library see http://playground.arduino.cc/Code/time

// RTC library see http://playground.arduino.cc/Code/time

// or http://www.pjrc.com/teensy/td_libs_DS1307RTC.html

// Change log:

// 1.01 Release by joo at https://github.com/9a/plotclock

// 1.02 Additional features implemented by Dave:

// - added ability to calibrate servofaktor seperately for left and right servos

// - added code to support DS1307, DS1337 and DS3231 real time clock chips

// - see http://www.pjrc.com/teensy/td_libs_DS1307RTC.html for how to hook up the real time clock

// delete or mark the next line as comment if you don't need these

#define CALIBRATION // enable calibration mode

//#define REALTIMECLOCK // enable real time clock

// When in calibration mode, adjust the following factor until the servos move exactly 90 degrees

#define SERVOFAKTORLEFT 650

#define SERVOFAKTORRIGHT 650

// Zero-position of left and right servo

// When in calibration mode, adjust the NULL-values so that the servo arms are at all times parallel

// either to the X or Y axis

#define SERVOLEFTNULL 2250

#define SERVORIGHTNULL 920

#define SERVOPINLIFT 2

#define SERVOPINLEFT 3

#define SERVOPINRIGHT 4

// lift positions of lifting servo

#define LIFT0 1080 // on drawing surface

#define LIFT1 925 // between numbers

#define LIFT2 725 // going towards sweeper

// speed of liftimg arm, higher is slower

#define LIFTSPEED 1500

// length of arms

#define L1 35

#define L2 55.1

#define L3 13.2

// origin points of left and right servo

#define O1X 22

#define O1Y -25

#define O2X 47

#define O2Y -25

#include <Time.h> // see http://playground.arduino.cc/Code/time

#include <Servo.h>

#ifdef REALTIMECLOCK

// for instructions on how to hook up a real time clock,

// see here -> http://www.pjrc.com/teensy/td_libs_DS1307RTC.html

// DS1307RTC works with the DS1307, DS1337 and DS3231 real time clock chips.

// Please run the SetTime example to initialize the time on new RTC chips and begin running.

#include <Wire.h>

#include <DS1307RTC.h> // see http://playground.arduino.cc/Code/time

#endif

int servoLift = 1500;

Servo servo1; //

Servo servo2; //

Servo servo3; //

volatile double lastX = 75;

volatile double lastY = 47.5;

int last_min = 0;

void setup()

{

#ifdef REALTIMECLOCK

Serial.begin(9600);

//while (!Serial) { ; } // wait for serial port to connect. Needed for Leonardo only

// Set current time only the first to values, hh,mm are needed

tmElements_t tm;

if (RTC.read(tm))

{

setTime(tm.Hour,tm.Minute,tm.Second,tm.Day,tm.Month,tm.Year);

Serial.println("DS1307 time is set OK.");

}

else

{

if (RTC.chipPresent())

{

Serial.println("DS1307 is stopped. Please run the SetTime example to initialize the time and begin running.");

}

else

{

Serial.println("DS1307 read error! Please check the circuitry.");

}

// Set current time only the first to values, hh,mm are needed

setTime(19,38,0,0,0,0);

}

#else

// Set current time only the first to values, hh,mm are needed

setTime(19,38,0,0,0,0);

#endif

drawTo(75.2, 47);

lift(0);

servo1.attach(SERVOPINLIFT); // lifting servo

servo2.attach(SERVOPINLEFT); // left servo

servo3.attach(SERVOPINRIGHT); // right servo

delay(1000);

}

void loop()

{

#ifdef CALIBRATION

// Servohorns will have 90° between movements, parallel to x and y axis

drawTo(-3, 29.2);

delay(500);

drawTo(74.1, 28);

delay(500);

#else

int i = 0;

if (last_min != minute()) {

if (!servo1.attached()) servo1.attach(SERVOPINLIFT);

if (!servo2.attached()) servo2.attach(SERVOPINLEFT);

if (!servo3.attached()) servo3.attach(SERVOPINRIGHT);

lift(0);

hour();

while ((i+1)*10 <= hour())

{

i++;

}

number(3, 3, 111, 1);

number(5, 25, i, 0.9);

number(19, 25, (hour()-i*10), 0.9);

number(28, 25, 11, 0.9);

i=0;

while ((i+1)*10 <= minute())

{

i++;

}

number(34, 25, i, 0.9);

number(48, 25, (minute()-i*10), 0.9);

lift(2);

drawTo(74.2, 47.5);

lift(1);

last_min = minute();

servo1.detach();

servo2.detach();

servo3.detach();

}

#endif

}

// Writing numeral with bx by being the bottom left originpoint. Scale 1 equals a 20 mm high font.

// The structure follows this principle: move to first startpoint of the numeral, lift down, draw numeral, lift up

void number(float bx, float by, int num, float scale) {

switch (num) {

case 0:

drawTo(bx + 12 * scale, by + 6 * scale);

lift(0);

bogenGZS(bx + 7 * scale, by + 10 * scale, 10 * scale, -0.8, 6.7, 0.5);

lift(1);

break;

case 1:

drawTo(bx + 3 * scale, by + 15 * scale);

lift(0);

drawTo(bx + 10 * scale, by + 20 * scale);

drawTo(bx + 10 * scale, by + 0 * scale);

lift(1);

break;

case 2:

drawTo(bx + 2 * scale, by + 12 * scale);

lift(0);

bogenUZS(bx + 8 * scale, by + 14 * scale, 6 * scale, 3, -0.8, 1);

drawTo(bx + 1 * scale, by + 0 * scale);

drawTo(bx + 12 * scale, by + 0 * scale);

lift(1);

break;

case 3:

drawTo(bx + 2 * scale, by + 17 * scale);

lift(0);

bogenUZS(bx + 5 * scale, by + 15 * scale, 5 * scale, 3, -2, 1);

bogenUZS(bx + 5 * scale, by + 5 * scale, 5 * scale, 1.57, -3, 1);

lift(1);

break;

case 4:

drawTo(bx + 10 * scale, by + 0 * scale);

lift(0);

drawTo(bx + 10 * scale, by + 20 * scale);

drawTo(bx + 2 * scale, by + 6 * scale);

drawTo(bx + 12 * scale, by + 6 * scale);

lift(1);

break;

case 5:

drawTo(bx + 2 * scale, by + 5 * scale);

lift(0);

bogenGZS(bx + 5 * scale, by + 6 * scale, 6 * scale, -2.5, 2, 1);

drawTo(bx + 5 * scale, by + 20 * scale);

drawTo(bx + 12 * scale, by + 20 * scale);

lift(1);

break;

case 6:

drawTo(bx + 2 * scale, by + 10 * scale);

lift(0);

bogenUZS(bx + 7 * scale, by + 6 * scale, 6 * scale, 2, -4.4, 1);

drawTo(bx + 11 * scale, by + 20 * scale);

lift(1);

break;

case 7:

drawTo(bx + 2 * scale, by + 20 * scale);

lift(0);

drawTo(bx + 12 * scale, by + 20 * scale);

drawTo(bx + 2 * scale, by + 0);

lift(1);

break;

case 8:

drawTo(bx + 5 * scale, by + 10 * scale);

lift(0);

bogenUZS(bx + 5 * scale, by + 15 * scale, 5 * scale, 4.7, -1.6, 1);

bogenGZS(bx + 5 * scale, by + 5 * scale, 5 * scale, -4.7, 2, 1);

lift(1);

break;

case 9:

drawTo(bx + 9 * scale, by + 11 * scale);

lift(0);

bogenUZS(bx + 7 * scale, by + 15 * scale, 5 * scale, 4, -0.5, 1);

drawTo(bx + 5 * scale, by + 0);

lift(1);

break;

case 111:

lift(0);

drawTo(70, 46);

drawTo(65, 43);

drawTo(65, 49);

drawTo(5, 49);

drawTo(5, 45);

drawTo(65, 45);

drawTo(65, 40);

drawTo(5, 40);

drawTo(5, 35);

drawTo(65, 35);

drawTo(65, 30);

drawTo(5, 30);

drawTo(5, 25);

drawTo(65, 25);

drawTo(65, 20);

drawTo(5, 20);

drawTo(60, 44);

drawTo(75.2, 47);

lift(2);

break;

case 11:

drawTo(bx + 5 * scale, by + 15 * scale);

lift(0);

bogenGZS(bx + 5 * scale, by + 15 * scale, 0.1 * scale, 1, -1, 1);

lift(1);

drawTo(bx + 5 * scale, by + 5 * scale);

lift(0);

bogenGZS(bx + 5 * scale, by + 5 * scale, 0.1 * scale, 1, -1, 1);

lift(1);

break;

}

}

void lift(char lift) {

switch (lift) {

// room to optimize !

case 0: //850

if (servoLift >= LIFT0) {

while (servoLift >= LIFT0)

{

servoLift--;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

else {

while (servoLift <= LIFT0) {

servoLift++;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

break;

case 1: //150

if (servoLift >= LIFT1) {

while (servoLift >= LIFT1) {

servoLift--;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

else {

while (servoLift <= LIFT1) {

servoLift++;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

break;

case 2:

if (servoLift >= LIFT2) {

while (servoLift >= LIFT2) {

servoLift--;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

else {

while (servoLift <= LIFT2) {

servoLift++;

servo1.writeMicroseconds(servoLift);

delayMicroseconds(LIFTSPEED);

}

}

break;

}

}

void bogenUZS(float bx, float by, float radius, int start, int ende, float sqee) {

float inkr = -0.05;

float count = 0;

do {

drawTo(sqee * radius * cos(start + count) + bx,

radius * sin(start + count) + by);

count += inkr;

}

while ((start + count) > ende);

}

void bogenGZS(float bx, float by, float radius, int start, int ende, float sqee) {

float inkr = 0.05;

float count = 0;

do {

drawTo(sqee * radius * cos(start + count) + bx,

radius * sin(start + count) + by);

count += inkr;

}

while ((start + count) <= ende);

}

void drawTo(double pX, double pY) {

double dx, dy, c;

int i;

// dx dy of new point

dx = pX - lastX;

dy = pY - lastY;

//path lenght in mm, times 4 equals 4 steps per mm

c = floor(4 * sqrt(dx * dx + dy * dy));

if (c < 1) c = 1;

for (i = 0; i <= c; i++) {

// draw line point by point

set_XY(lastX + (i * dx / c), lastY + (i * dy / c));

}

lastX = pX;

lastY = pY;

}

double return_angle(double a, double b, double c) {

// cosine rule for angle between c and a

return acos((a * a + c * c - b * b) / (2 * a * c));

}

void set_XY(double Tx, double Ty)

{

delay(1);

double dx, dy, c, a1, a2, Hx, Hy;

// calculate triangle between pen, servoLeft and arm joint

// cartesian dx/dy

dx = Tx - O1X;

dy = Ty - O1Y;

// polar lemgth (c) and angle (a1)

c = sqrt(dx * dx + dy * dy); //

a1 = atan2(dy, dx); //

a2 = return_angle(L1, L2, c);

servo2.writeMicroseconds(floor(((a2 + a1 - M_PI) * SERVOFAKTORLEFT) + SERVOLEFTNULL));

// calculate joinr arm point for triangle of the right servo arm

a2 = return_angle(L2, L1, c);

Hx = Tx + L3 * cos((a1 - a2 + 0.621) + M_PI); //36,5°

Hy = Ty + L3 * sin((a1 - a2 + 0.621) + M_PI);

// calculate triangle between pen joint, servoRight and arm joint

dx = Hx - O2X;

dy = Hy - O2Y;

c = sqrt(dx * dx + dy * dy);

a1 = atan2(dy, dx);

a2 = return_angle(L1, (L2 - L3), c);

servo3.writeMicroseconds(floor(((a1 - a2) * SERVOFAKTORRIGHT) + SERVORIGHTNULL));

}配線はこちらになります。

上のcodeを書き込むとサーボモーターが動きます。

今日はここまでです。ありがとうございました。

この記事が気に入ったらサポートをしてみませんか?