About the machine for the music video for Buffalo Daughter "Jazz"

This time, I made a video for Buffalo Daughter's song "Jazz".

I directed, edited, and created the video by myself, including the mechanical components.

This is the piece.

Here is a technical description of the video.

The elements are this time

・Retroreflective materials

・Mechatronics of multiple axes

"The cybernetic Bunraku"

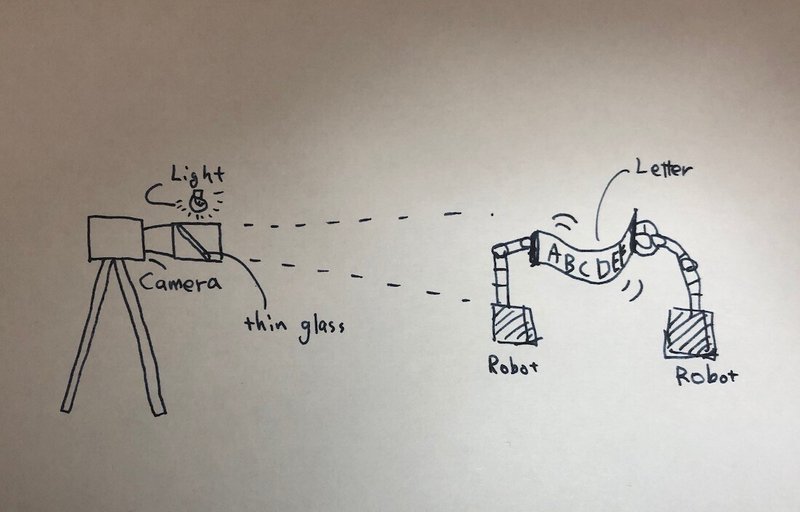

I was asked to create a lyric video that would be like a lyric video, but instead of using video editing software to display text, we decided to create a cybernetic BUNRAKU (Japanese traditional puppet show) in which a sheet with printed text (later changed to a cutting sheet instead of printing) is flown by a robotic arm in front of the camera.

The lyric content of the text suggests that we wanted to create a scene that gradually brightens from a dark scene, and there was a fear that this would not be captured in the image, so we decided to make the text glow. We decided to use a material called retroreflector, which is used for road signs, etc., and a light with an integrated lens.

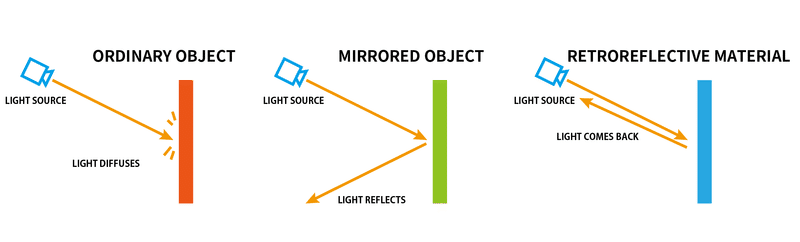

This material has the special property of returning the light from the light source to the location of the light source. This is quite unusual.

The problem is that the center of the camera lens and the lighting lamps must be placed close together to capture a strong reflection. The car driver's eyes and the headlights are far enough away, but the road sign is also far enough away to see the reflection. But the truth is that the maximum brightness and glare is seen when the face is right next to the headlights.

It is not easy to align the center of the camera lens with the axis of the light source. In the case of a smartphone, the lens is very small and the LED light source is placed very close to the lens. In fact, using a smartphone and the smartphone's built-in light, it is easy to capture a clean reflection without the need for a special light source.

However, in this case, I wanted the text to stand out from the background, so I did not want to focus on the front and back of the text. A smartphone camera with a small lens that is clear and sharp is not suitable for this purpose. If you use a regular digital camera, if you place the light in the center of the lens, you will only get the butt of the light.

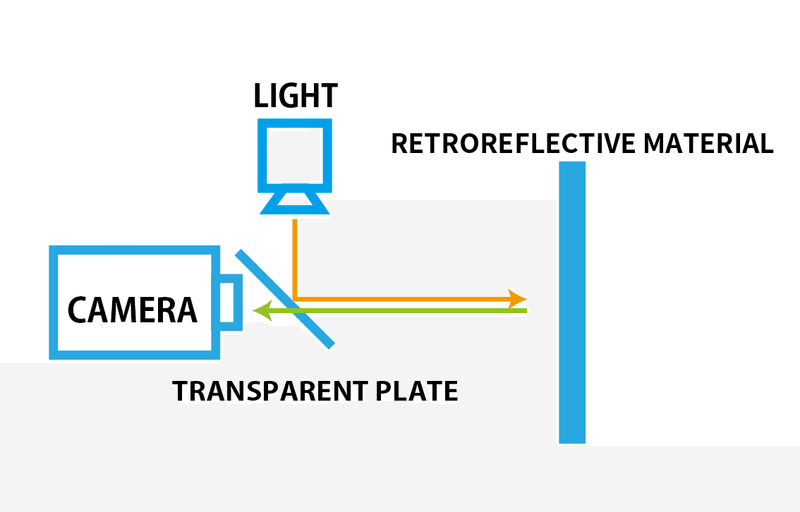

Therefore, a transparent plate is placed in front of the lens to split the beam.

The diagram is as follows.

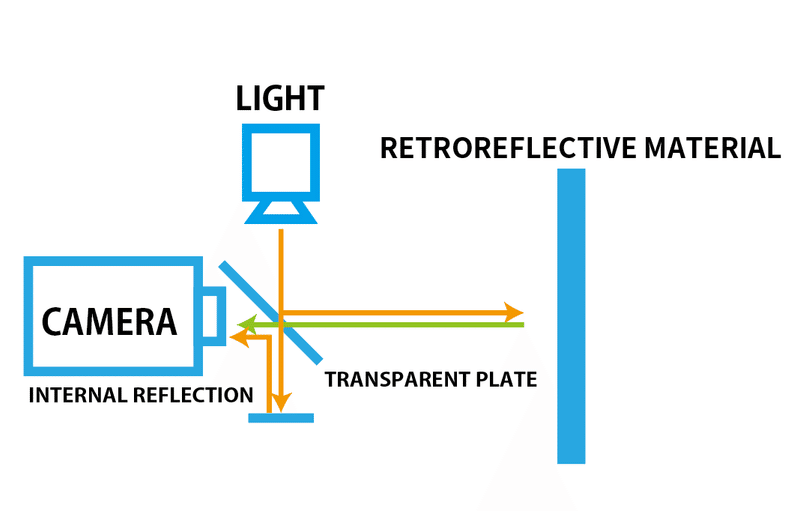

In reality, light is not fully reflected by the transparency plate, so the amount of light that slips through is reflected inside the device and enters the lens. This causes extra flare.

It is complicated, but the diagram is as follows.

In order to minimize unnecessary reflections inside the device as much as possible, an inner surface antireflection material for optical equipment made in Japan was used. Still, strong light will be reflected, but we give up on that. The screen will turn out nice and white, so I'll take that as a good sign of my injury.

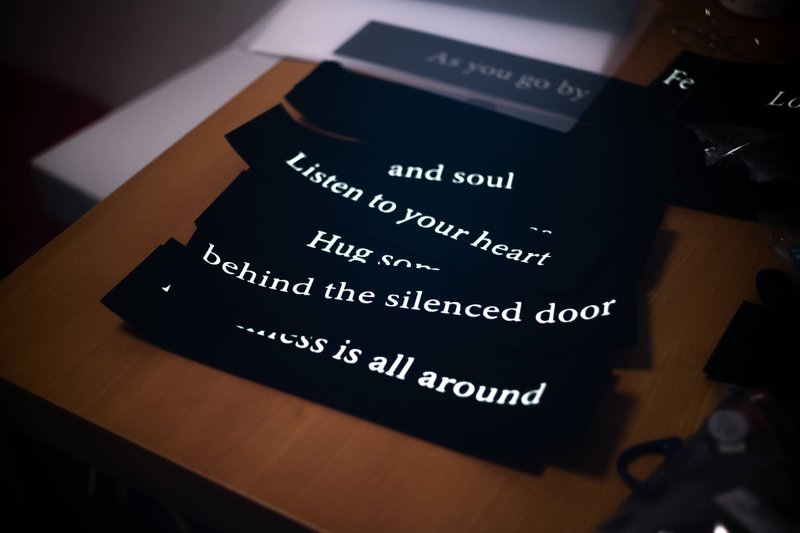

Letter sheets were also created by affixing letters made of retroreflective material on top of anti-reflective material.

This gives a very strong contrast when the light is shone on the image, obtaining both white skips and blackouts. It is now possible to obtain very special images.

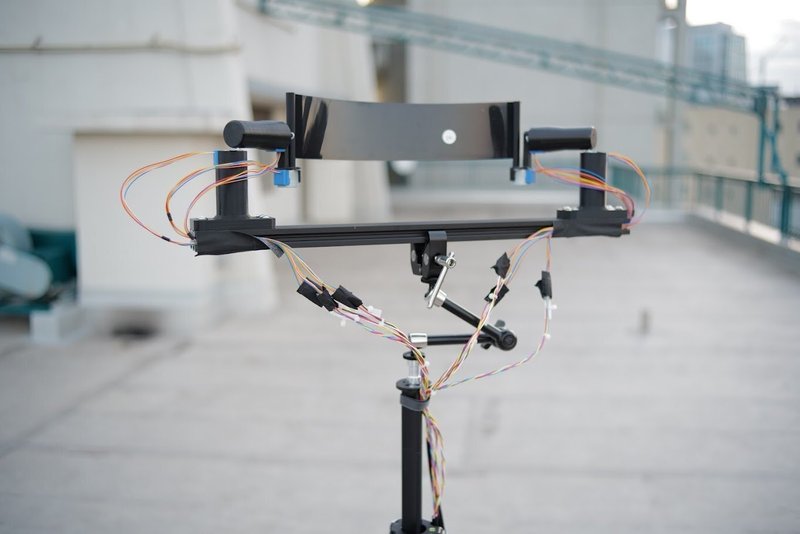

And here's what the camera that takes pictures of it looks like.

It is a strange thing: an ordinary mirrorless SLR, a standard lens, a reflector box and a high-intensity penlight sticking out. The focal length of the lens is an old 50 mm, f/2 lens.

Light comes out from the center of the camera lens like this. It is mysterious.

Placing the imaging system and the light source for projection on the same axis (conjugate) has many advantages when projecting in real time while shooting, and there are many precedents, including the research on optical camouflage by Dr. Inami (@drinami). My lamp is just an illumination, but it is originally intended for more intelligent applications.

Well ...

I made a robot that flutters a sheet of letters.

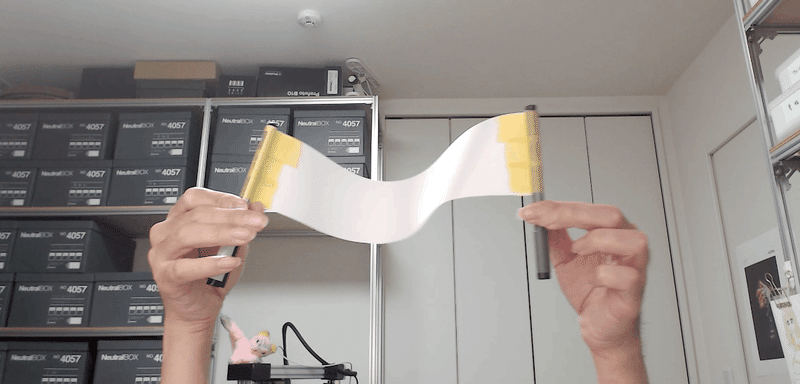

First, test it by hand.

As you can see when you try it, it seems that no matter how many motorized axes you have, it is not enough to make it move naturally. Nature is amazing. I managed to reduce the number of axes and compromised with 3 axes per side, 6 axes in total.

We decided to control the small motor built into the louver of the air conditioner.

This is a video of a prior example by a predecessor.

It was very informative to see how this motor and structure could be made to move with such precision.

Thanks to this author (Electron Dust).

I'll skip ahead a bit, but it's done.

Once again, please take a look at the finished film.

この記事が気に入ったらサポートをしてみませんか?