EDMONDS SHOE COの研究 1918-1922

THE FOUNDER

FOUNDER - W.A.Edmonds

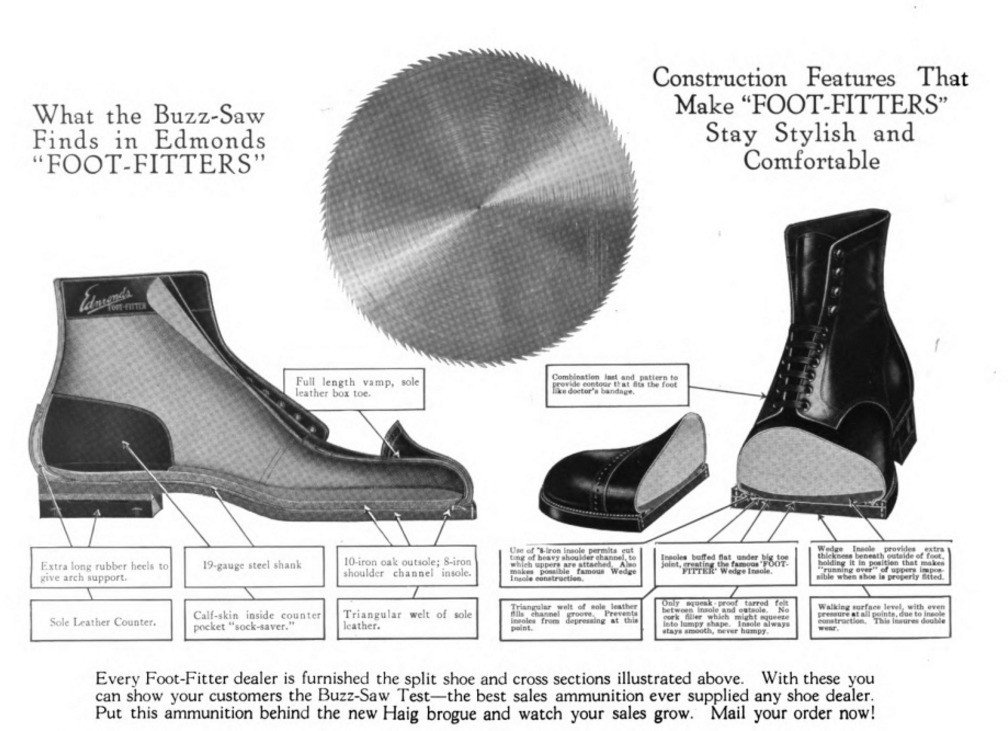

FOOT FITTER

Boot and shoe recorder versus 82 (October - November 1922)

1900

1908

NEW CONCERN GROWS FAST.

Harsh, Smith & Edmonds Sell High Grade, Heavy Work Shoes to Retail Trade in Central West—Young Men Comprising Firm Were Formerly With St. Louis Manufacturers-Occupy Five Story Brick Building.

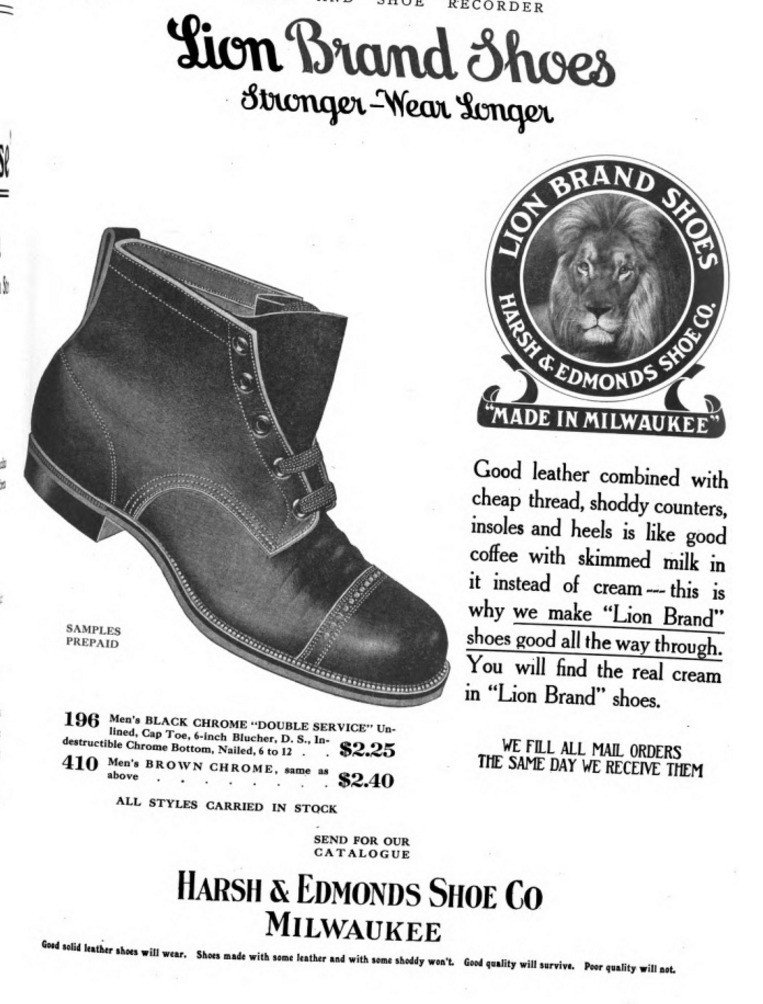

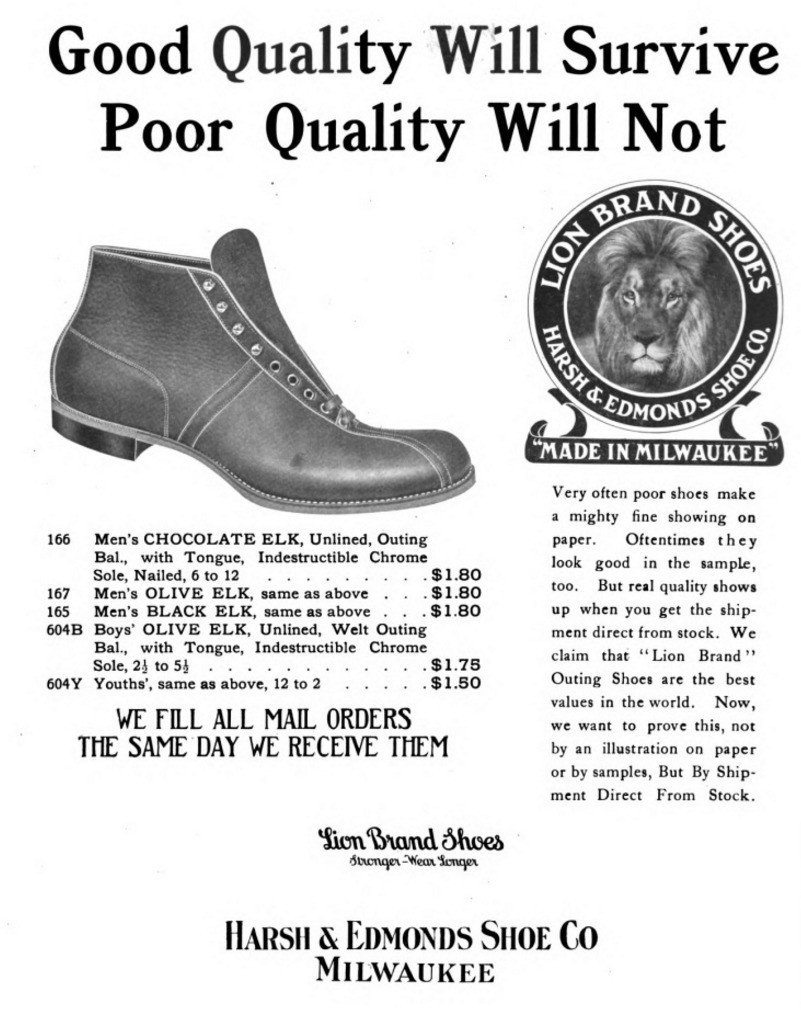

The Harsh, Smith & Edmonds Shoe Co. are manufacturers of Lion Brand High Grade Heavy Shoes for men and boys. They have been in business in Milwaukee two years and sell their goods to the retail trade in the Central West. They employ about 275 people, making nothing but work shoes. The company occupies a large five-story brick building. The firm is composed of young men of ability and push. Those comprising the manufacturing end of the business were formerly with large shoe manufacturing concerns of St. Louis. The officers are: George R. Harsh, president; W. A. Edmonds, vice-president; E. A. Long, treasurer, and C. O. Chapline, secretary; these gentlemen, with J. M. Thornton also comprise the directorate.

Boot and shoe recorder v. 53 (June-July 1908).

1910

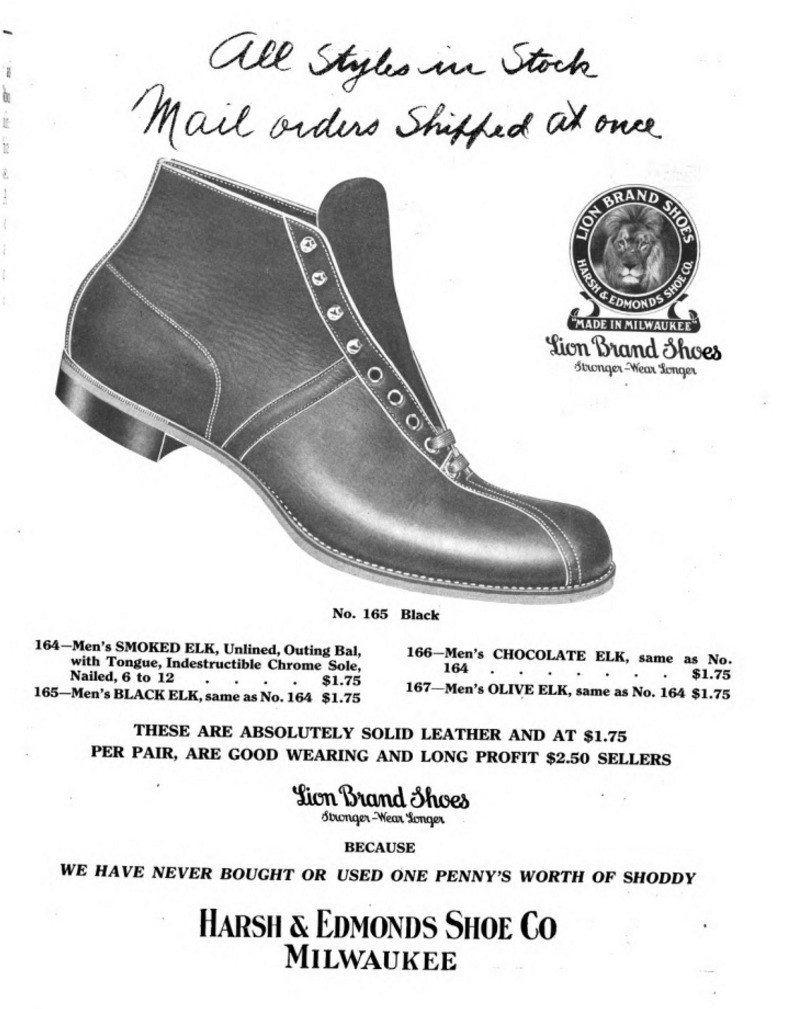

Hirsch & Edmonds shoes co Milwaukee WI for the 1910 Lion Brand

1911

Boot and shoe recorder V. 60 (January 1912 from December 1911).

Boot and shoe recorder V. 60 (January 1912 from December 1911).

Boot and shoe recorder V. 60 (January 1912 from December 1911).

Boot and shoe recorder V. 60 (January 1912 from December 1911).

1912

Boot and shoe recorder pair 60 (month - March 1912).

Boot and shoe recorder V. 60 (January 1912 from December 1911).

Boot and shoe recorder pair 60 (month - March 1912).

Boot and shoe recorder pair 60 (month - March 1912).

Boot and shoe recorder pair 60 (month - March 1912).

Boot and shoe recorder versus 61 (April - May 1912).

Boot and shoe recorder versus 61 (April - May 1912).

Boot and shoe recorder versus 61 (April - May 1912).

Boot and shoe recorder versus 61 (April - May 1912).

Boot and shoe recorder versus 61 (April - May 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

Boot and shoe recorder versus 61 (July from June to 1912).

1913

Hirsch & Edmonds Shoes Co., Ltd., of Milwaukee, for the number of eastern and western part of the shoe manufacturer is large, issued the following letter: "We are, it is a return of the wear of shoes, shoes industry is too late very consideration of the worst abuse that, unless the shoes has failed, for the past some time, we are actively, in order to enable the anycredit for for the repair or return wear shoes refusal to have. we are, but have lost a few customers, most of the GT tlhose that leave us for any length of time have come a alternating current. "we are, more and more manufacturers, this is if their cost what grade FI, they are more than a manufacturer to refuse to impose the believe that would decide was time to stop the practice, it is to be wiped out completely abuse will you briefly. We are, you have to consider the issue carefully, we believe you decided to take a stand for justice. "Much higher evaluation letter to express your opinion will be very in the subject line." In fact, all of the recipients of the above character frequently, as a result, a significant loss of return of wear of the shoes at the time of the manufacturer When accompanied by the destruction of the reply business trade disputes and is a fruitful source of disagreement to the effect that a growing abuse of between manufacturers and retailers. aggregate value of exactly wear shoes it is difficult to estimate returned every year across the country of the manufacturer There, it will certainly reach to millions of people some of the shoes of dollars.At 1 January of the National Association of manufacturers conference, is it on the other hand, the dealer is the arrangement of the wear shoes, free of charge, not only to the dealer , we have resolved that it is a loss and illegal source of the manufacturer ". Patent or no allowance should be made for the shoes made from patent leather and cloth - manufacturer, with the exception of the construction and obvious defects with disabilities within the material, give credit for any of shoes that have been worn No is that it has been resolved. It further manufacturers, however, that does not give credit for any of shoes that have been worn, be resolved as shoes have given, it is allowed to fair credit for such wear without. "Before he more than 150 of the character was written, by the manufacturer in this article of the writer has Hirsch & Edmonds Shoe Corporation, described their attitude to one of the return

March 5, 1913

Boot and shoe recorder pair 63 (April - May 1913).

Boot and shoe recorder pair 63 (April - May 1913).

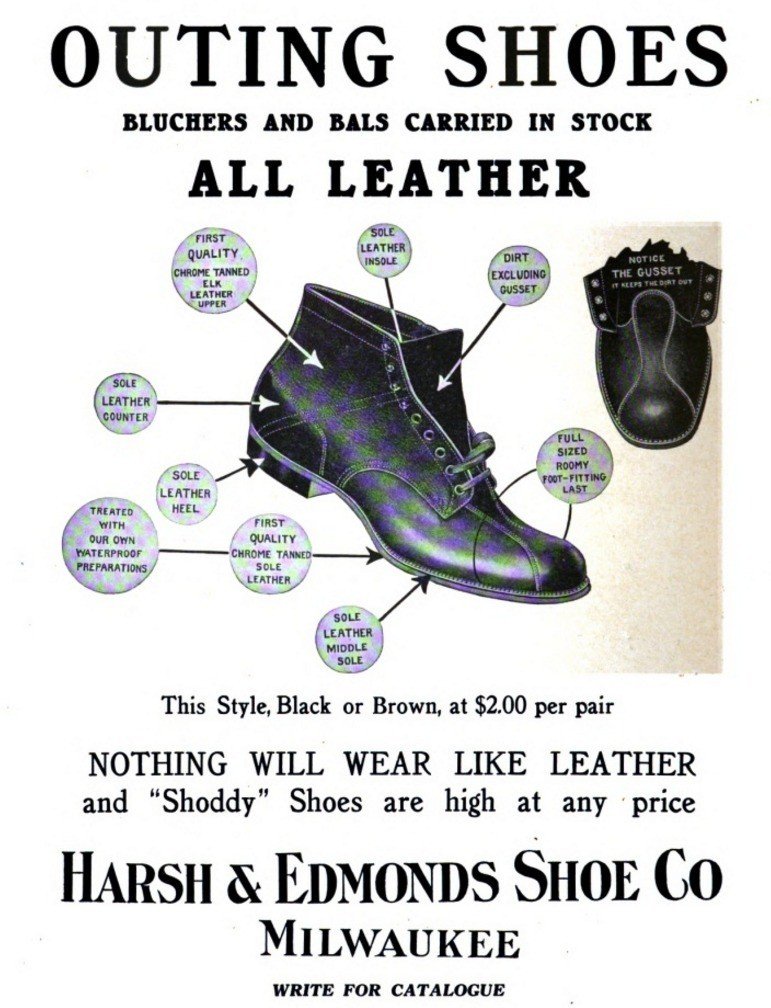

Boot and shoe recorder pair 63 (July from June to 1913).

Hirsch & Edmonds Shoe Corporation, Milwaukee, to take advantage of their large-scale line of all of the leather go out of shoes, is an annular trade with charm of the folder, continue ready for OOR instant shipment on the FL year. They are made of more of VE in the "ER is a dozen 1 shipped to the current order dealers to O Fi from Fi, shoes shown in the invoice payable October 1, both of the folder, market price is very It is attractive.

June 4, 1913

Boot and shoe recorder pair 63 (July from June to 1913).

Boot and shoe recorder pair 63 (July from June to 1913).

Boot and shoe recorder pair 63 (July from June to 1913).

Now, now you are in full operation in the output of about 3.000 set of every day, all such dealers successfully exploited go out of shoes, such as now imperatively need, and another of its general up-well received folder who are the trade an annular, Co .. Milwaukee the heat of the shoes of harsh & Edmonds can be found here. Ten illustrations of attractive model is shown. All -styles shown in a special new price list on June 25 with is ready for immediate shipment, it is carried in stock.

July 16, 1913

Harsh Edmonds shoes Co., Ltd., is well-known in Milwaukee are manufactu who, on July 22, in a lot of enthusiasm, which is evinced by all attendees, a general convention of their salesman here It was held. WA Edmonds, the company's vice president, has been reported to show the corresponding six-month increase of before they are shipments 250,000 years for this year's first six months. At present, production of the factory, the corresponding period of 1912, 3,000 pairs per day with 25% of the gain above their output, which is

August 6, 1913

Boot and shoe recorder pair 63 (August - September 1913).

Boot and shoe recorder pair 63 (August - September 1913).

Boot and shoe recorder pair 63 (August - September 1913).

Boot and shoe recorder pair 63 (August - September 1913).

Boot and shoe recorder pair 63 (August - September 1913).

Hirsch & Edmonds Shoe Corporation, Milwaukee has been transferred to the Indiana territory. The company, with sales of the road, formerly Mr. McChesney conducted a retail shoe store in Bristol, they all Milwaukee of wholesalers and manufacturers of typical of the canvass of the hands of Tenn.A indicating that busy in the shipment of autumn the majority of forces in the region now that you have to place him of the old days of trade in. New line of spring as completed now, it indicates -even for a very well of "Cream City" footwear.

1913 October 1,

George R.Harsh, is an important first step that should be taken, as well, in this association, seems to be for all of Tanner of the country and severe Edmonds Shoe Corp. Tanners Association, before the delivery Addrss, it makes a good leather. Buy a good leather. "Good" I mean the best by leather

1913 11 May 19

1914

Boot and shoe recorder V. 64 (January 1914 from December 1913).

Hirsch & Edmonds Shoe Corporation, Milwaukee, enjoys a good season. They're averaging a 3000 pair of work shoes of Lion brand per day.

January 7, 1914

It IS reported that the Harsh & Edmonds Shoe Co., Milwaukee, intend to build a new factory on Reed Street at an estimated cost of about $60,000.H. I. Esser has drawn up architect’s plans for the structure, which is to be a reinforced and steel con— struction, seven stories and a basement high, and 80 x 160 feet in dimensions.

March 11 1914

A Profit Sharing Plan

G. A. M. Powers, who has charge of the department of industrial efficiency of the Harsh & Edmonds Shoe Co., Milwaukee, is quoted as saying: “The underlying thought in our profit-sharing with employees (begun about six weeks ago) is to induce efficiency and thrift. “We have on our pay roll 420 employees, out of whom 229 have applied and are stockholders by the OUR SLOGAN If Not, Why ARE YOU MAKING MONEY? Not trying to fool the people part of the time, but making and selling the people honest leather shoes all the time.

April 15 1914

Breaks Ground for New Building

Breaking ground for the new Reed Street addition to the plant of the Harsh & Edmonds Shoe Co.,at Maple and Hanover Streets, Milwaukee, commenced last week. The building will have a frontage i of 80 feet on Reed Street and will be 160 feet deep and seven stories high. The construction will be of concrete and brick and steel skeleton. The structure will be ready for Occupancy July I. The cost will be $80,000. The entire building will be equipped with an automatic sprinkler system. The north and cast walls of the building will be mostly steel sash and glass to assure an abundance of light. When this new addition is completed, with their present plant, it will give the Harsh & Edmonds Shoe Co. a total ground area of 150 x 300, six stories sin high, and will be one of the largest shoe plants in the West.

April 22 1914

The Harsh & Edmonds Shoe Company, of Milwaukee,are reported contemplating the building of a tannery to supply leather for their shoe factory, which requires about a million dollars’ worth of leather annually.

June 7 1914

George R. Harsh, president of the Harsh & Edmonds Shoe Co., Milwaukee, announces that it will build a $125,000 tannery with an output of $1,000,000 worth of leather a year. The capital has been increased to $750,000. The “Badger State” lists the opening of the following new shoe stores and shoe departments during the past week

June 27 1914

Injured in Auto Overturned

William E. Edmonds, of the Harsh & Edmonds Shoe Co., Milwaukee, and W. S. Caswell were both injured when an automobile in which they were riding overturned on the Blue Mound road last week. Defective steering gear is believed to have caused the accident. The car randown an embankment and turned turtle.

October 3 1914

Completing New Tannery

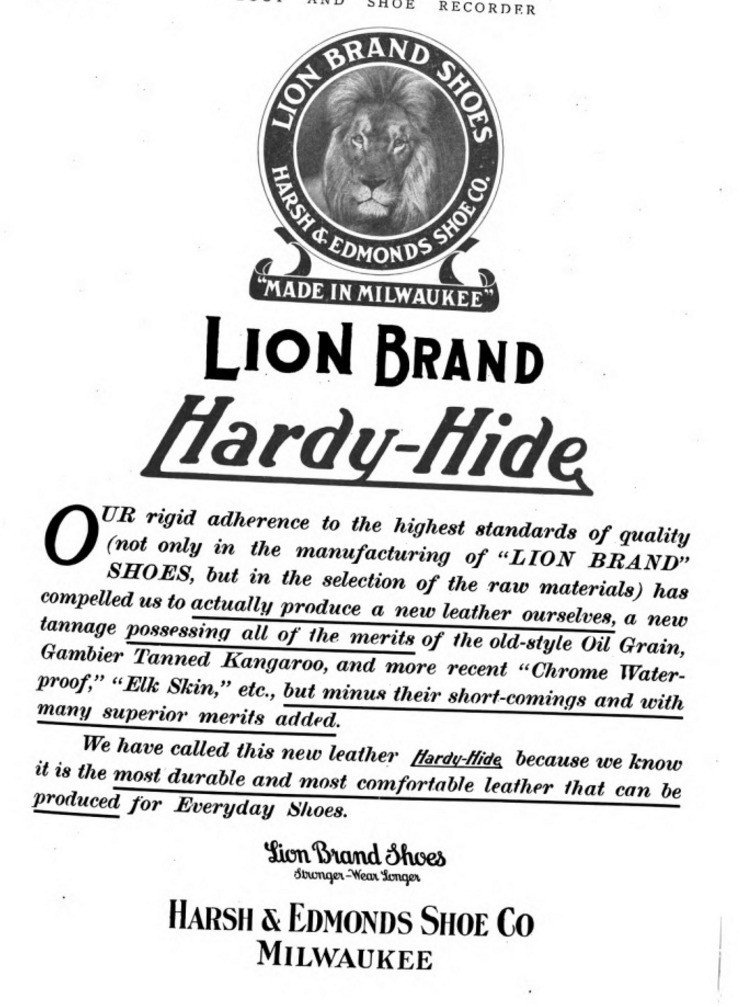

The new tannery of the Harsh & Edmonds Shoe CO-,adjoining their shoe factory in Milwaukee, is nearly finished. Messrs. Sheldon and Fredericks, who are in charge of the tannery operations, expect to wet the first hides about October 15. The new plate is a model of its kind, fitted with the latest machinery and equipment. It is estimated that between 500 and 600 sides of elk and black waterproof chrome retanned, as well as some chrome sole, will be tanned daily, all for consumption in the shoe factory of Harsh & Edmonds. Adjoining the tannery is a large storehouse which will be devoted to hides, liquors and the like. An artesian well is being sunk to obtain abundance of water. All the paddles and machinery will be motor-driven.

October 24 1914

H. C. Freeman and J. W. McHenry, of Milwaukee, have purchased the controlling interest in the Tomahawk Shoe Co., of Tomahawk, Wis. J. W. Quance, who has been factory superintendent since the business was established in March, 1913, has resigned his position and disposed of his firm interest. At the reorganization meeting the following new officers were elected: President and treasurer, H. C. Freeman; vice-president, R. B. Tweedy; secretary and assistant treasurer, J. W. McHenry. Messrs. Freeman and McHenry are experienced shoe factory men. Mr. Freeman was for eight years superintendent of the Harsh & Edmonds Shoe Co. of Milwaukee. Mr. McHenry gained experience with the Fitzgerald, Phelps & Fargo Shoe Co., of the same city. The new management plan to put the factory into operation again at the earliest possible moment. The line of women's and misses’ footwear hitherto manufactured will, however, now be discontinued and a line of boy's shoes will be specialized upon.

November 14 1914

1915

Boot and shoe recorder v. 67 (Apr.-May 1915).

“Crops, Money and Credits”

All Plentiful, and Good Business“W'e look for a big business this fall for numerous reasons: Chief among them are that our farm products will be worth about ten billion dollars, our exports are exceeding our imports one hundred millions per month, our banks have never had such large deposits, and credit has vnever been so free to legitimate enterprises. “All of this encourages manufacturers and other employers to go ahead. This gives employment to everyone who really wants to work, and of course employment makes a demand for all kinds of merchandise, including shoes.“All that is needed now is confidence, and a full realization of these facts will bring confidence. and. with it a big volume of business. This condition is even now well under way as is shown by our orders for immediate shipment being far in excess of last year.” HARSH & EDMONDS SIHOE CO., Milwaukee, \Vis, Geo. R. Harsh, Pres.

September 4 1915

Harsh & Edmonds Increasing Output

The Harsh & Edmonds Shoe Co. is meeting with unusual success in its business this year. So great is the demand for their medium priced heavy shoe that they are increasing the factory output from 2,400 to 3,600 pairs per day. To date their business shows an increase as compared with last year of $136,- 723.60, total sales to date the current year amounting to $1,648,- 115.08.

November 27 1915

Chatham NY Courier 1915 Grayscale - 0113.pdf

1916

Harsh & Edmonds Will Build

The Harsh & Edmonds Shoe Company will erect four additional stories to their factory at 694- Hanover street. The plans call for steel skeleton, brick and mill construction, 530x160 feet. The cost is estimated at $50,000.

January 22, 1916

General Prosperity Indicated by Factory

W. A. Edmonds, of the Harsh-Edmonds Shoe Co..wel| known Milwaukee manufacturers of work shoes, says that business has undergone a most remarkable improvement and that people are spending money freely. It- is this condition which accounts for the $30,000 addition which will be built to their plant. Milwaukee is to be congratulated, he said, for not having taken a dollar’s worth of war business.

February 19, 1916

Prosperity in Evidence

At least two Milwaukee shoe manufacturing companies believe that the present general prosperity in the United States is permanent and will not cease with the close of the war, and they are preparing to erect xtensive addition to their factories. They are the Harsh & Edmonds Shoe Co. and the Weyenberg Shoe Mfg. Co. In each case, officials of the company are this we k quoted as saying that prospects for continued “good times" are sufficient to warrant extensive business expansion. At each factory it was said that the European war has had only an indirect effect on our national business. "I don’t believe that a dollar's worth of shoe business has been placed with manufacturers in Milwaukee, or for that matter, in the entire West," said W. A. Edmonds. The same thought was reiterated at the Weyenberg officers. “A little more than two years ago," continued Mr. Edmonds, “when we could have taken advantage of war contracts on account of the general business depression, we could not obtain them, and now that we are rushed to fill our urgent domestic requirements, we would not accept them even if offered to us." The Harsh & Edmonds Shoe Co. on Wednesday last, took out a permit to erect a $31,000 factory addition of four stories to its already three-story plant at Reed and Maple Streets. The Weyenberg Company received a permit for a $30,000 addition to its factory at Harmon and Hubbard Streets.

March 4-, 1916

H&E. Factory Adidtions Ready

The new four-story addition to the Harsh and Edmonds Shoe Co., has been completed and the machinery installed. The plant now has a capacity of 4,000 pairs of shoes daily. The heavy demand for their work shoes is demonstrated by the output of their tannery, which produces daily over 10,000 square feet of upper leather and chrome soles.

May 27, 1916

1917

Boot and shoe recorder v. 71 (Apr.-May 1917).

Boot and shoe recorder v. 71 (Apr.-May 1917).

As an example of practical co-operation with the government, we reproduce in full the letter sent by George R. Harsh, of Harsh & Edmonds Shoe Co., to the secretary of war. Mr. Harsh also says: “It is our opinion that packers, tanners and shoe manufacturers owe it to our government to furnish quickly‘ and without profit to themselves, all the shoes and other leather goods required. “Our country can be enormously benefited in quick service and financial support through lower cost, if the three branches of our industry will co-operate to the fullest extent in producing at cost. “In fact, it is only in that way that the greatest good can be done, and for that reason, we ask your co-operation and your best efforts towards writing packers, tanners and shoe manufacturers into one great unit to serve, as best we can. the country we love and are proud to call our own."

April 14, 1917

Boot and shoe recorder v. 71 (Apr.-May 1917).

Boot and shoe recorder v. 71 (Apr.-May 1917).

Boot and shoe recorder v. 71 (Apr.-May 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (Apr.-May 1917)

Boot and shoe recorder v. 71 (Apr.-May 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

A. G. SHOWERS IN SOUTHERN ILLINOIS

Mr. Showers has.practically doubled the business of the Harsh & Edmonds Shoe Co., in Southern Illinois since taking the territory three years ago. He is seen here in front of the store of one of his progressive customers, Rogers Bros., Decatur. This firm has been in the shoe business for sixteen years at Lincoln, Ill., and nineteen years at Decatur, consecutively. POPULARITY OF MILITARY STYLES DEVELOPING ‘ The two practical models of boots of military type shoWn above are the product of Harsh & Edmonds Shoe Co., Milwaukee. At the right is a tan Hardy Hide 16-mch whole leg boot, cap toe high cut with soft box, full vamp. grain gusset. The boot at the left is a Hardy Hide, 6-mch Blucher, cap toe with soft box, brown duck cemented lining, full vamp, grain gusset. These are also made up of a nch dark brown Hardy Hide leather

July 28, 1917

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71 (June-July 1917).

Boot and shoe recorder v. 71-72 (Aug.-Sept. 1917).

W P. CLEMENS

With Hylo Novelty Mfg. Co., of Jefferson City, Mo. affiliation with the Iowa Association, when he and Dave Marks, who is now sales manager for the Harsh & Edmonds Shoe Co., Milwaukee, worked so hard in building the Iowa Shoe Retailers’ Association, which is one of the livest now affiliated with the National body.

Boot and shoe recorder v. 72 (Dec. 1917-Jan. 1918).

A FIFTY PER CENT GAIN

Indicating Growth of Milwaukee Shoemaking The Harsh & Edmonds Shoe Co. is increasing its factory capacity by the erection of a new building. Business has grown rapidly this year with this concern, which necessitated a larger output. Dave Marks, sales manager, says that the year will close with fifty per cent gain over 1916. George Harsh is well known for doing things in a big way, and accordingly, he demonstrated this to his six hundred and fifty employees by presenting each with a Thrift Stamp card as a Christmas gift. He has likewise bought six hundred Red Cross memberships for his employees. The sales manager, Mr. Marks, said that “business is good, and the goose hangs high."

Dec. 29, 1917

1918

BIGGEST BUSINESS IN HISTORY

97 Fer Cent Gain in Dave Nlarks, sales manager Sales Reported of Harsh 8t Edmonds Shoe Co., reflects the prosperity of the Milwaukee shoe market in the following statement:-—- “For the first four weeks, ending February 21st, we show a gain in sales of 97 per cent over the same period of a year ago. “Our shipments show a gain of 35 per cent over the same period of last year. Our gain in shipments could be considerably larger, but we are unable to make shipments to points east of the Mississippi River on account of embargoes on all freight. “We are experiencing the biggest business in our history in every part of the country. The prospects for the future look very good.”

March 2, 1918

Harsh&Edmonds are enlarging and improving greatly their executive ofiices, using one entire side of their factory building for this purpose. Dave Marks, sales manager, reports a tremendous increase in business. Herman Short and L. Wallace, their two sales leaders, have reported advance orders booked for next season, $118,000 from Oklahoma and $109,000 from Texas respectively.

May 4, 1918

The Harsh & Chapline Shoe Co.

Boot and shoe recorder versus 73 (April - May 1918).

FIRM IS NOW HARSH & CHAPLINE

Recognition of Services C. O. Chapline, vice-presi-with Harsh & Edmonds dent and treasurer since January, 1917, of the Harsh & Edmonds Shoe Co. of Milwaukee, has been accorded recognition of his activities in this concern by the 'ncorporation of his name in that of the firm, which now becomes Harsh & Chapline. Mr. Chapline has been sales manager for ten years previous to this latest move, and as his policies as such have been a great factor in the development of the business, the same will be continued now by D. A. Marks, who has traveled Iowa for the past six years in the interests of Harsh & Edmonds, and who now succeeds Mr. Chapline as sales manager. Mr. Chapline is active general manager of the entire factory and tannery, and is one of the live wire young men of the trade, although only 38 years of age. Harsh & Chapline are now making 4,000 pairs of shoes daily, work shoes exclusively, tanning all their upper leather and chrome soles. Mr. Chapline is generally well liked among the trade, and this feeling of regard is extended throughout the factory, thus making for the Harsh & Chapline Co. a tremendously loyal and energetic organization. C. O. Schonberg, who has traveled South Carolina for the past year for Harsh & Edmonds, has returned to his home in Milwaukee to prepare for induction into the service in the very near future. Mr. Schonberg grew up as a boy in the office, and upon taking up the South Carolina sales in one year increased the business 300 per cent, and gained the Harsh & Edmonds medal for sales efficiency.

May 11, 1918

Greenfield MA Recorder 1918-1919 - 0238.pdf

1929 Ad Hardyhide Work Shoes Harsh Chapline Milwaukee Wisconsin Leather YBSR1

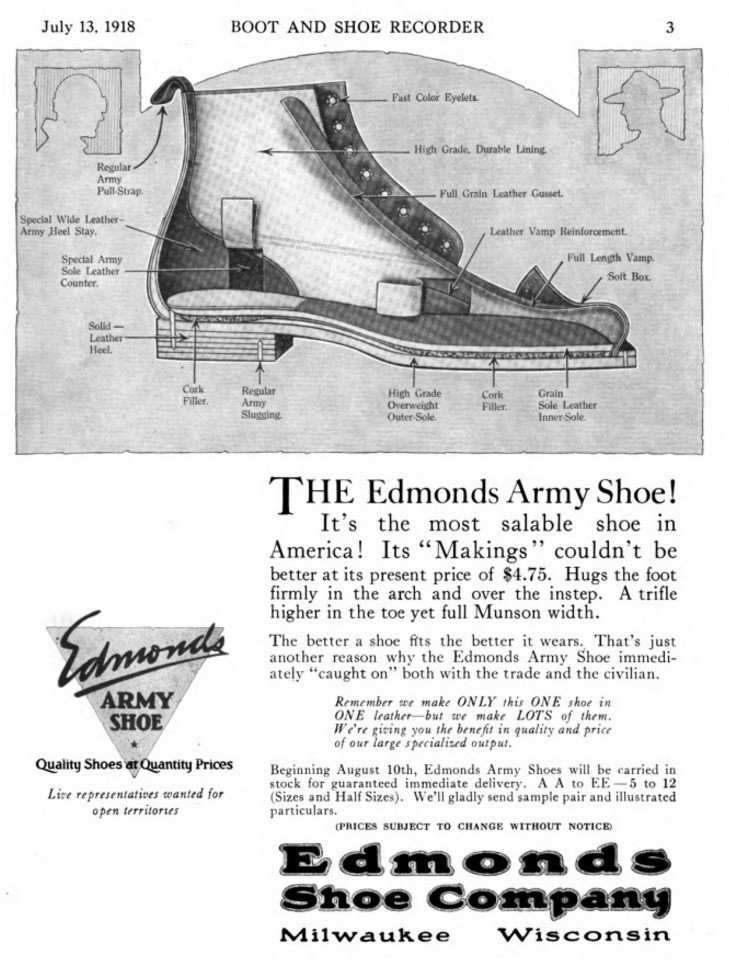

EDMONDS SHOE COMPANY 1918

New Shoe Factory for Milwaukee

Recently there has been incorporated in Milwaukee a new organization known as the Edmonds Shoe Company, the original incorporators being W. A. Edmonds and G. E. Musebeck. Mr. Edmonds was formerly connected with the Harsh & Edmonds Shoe Company, and Mr. MIusebeck was for a long period of years connected with the United Shoe Machinery Company, and more recently with a number of leading western shoe manufacturers. Associated with these gentlemen is C. A. Dickens, who has been highly successful in sales and advertising promotion, and G. 0. Peterson, who has within the last few years acquired an enviable reputation in oflice management. The factory, which is located at Burleigh and \Veil Streets, will be devoted to the manufacture of but one shoe, known as the Edmonds Army Shoe. The company has selected the latest, improved Dr. Munson regulation U. S. Army last, but has made some changes so as to insure better fitting qualities, and thus better adapt the last for civilian purposes. This shoe, upon which this new company will specialize. will be carried in stock in sizes from 5 to 12 and widths A to EE. Post Graduate Course in Practipedics

June 8, 1918

Milwaukee, Wis.-—Edmonds Shoe shoe manufacturers, recently incorporated, the original incorporators being Mr. W. A. Edmonds and Mr. G. E. Musebcck. Mr. Edmonds was formerly connected with the Harsh&Edmonds Shoe Co. and Mr. Musteback was connected with the United Shoe Machinery Co., and more recently with a number of leading Western shoe manufacturers. Associated with these gentlemen is Mr. C. A. Dickens and Mr. G. 0. Peterson. Factory located at Burleigh and Well Sts. Capital, $l00,000. Madison, Ms.—The Outlet Store, shoes, etc., incorporated with capital of $25,000.Wind Lake, Wis.—Krogstad 8: Fries, shoes, etc.,dissolved partnership: succeeded by Krogstad.Milwaukee, Wis.—Kroeger Bros. Co., shoes, etc.,capital increased to $2,500,000.Diagonal, Ia.~—l-‘armers Co-operative Exchange,dry ssgds and shoes, incorporated with capital of S10, . Uniontown, Ala.--C. C. Morgan 6t Co., shoes, etc., out of business.

June 22, 1918

ARMY SHOE

reference photo WW1 ARMY BOOT MUNSON LAST

Boot and shoe recorder v. 73 (June-July 1918).

Boot and shoe recorder v. 73 (June-July 1918).

“ARMY SHOE”JENNINGS

En thusiaslic Salesman Picks New Name “Army Shoe” Jennings, formerly covering Ohio with a general line, now covers the central portion of the Keystone State with the “Shortest Line in the \Vorld.” Nlr. Jennings is selling the Edmonds U. S. Army shoe made by the Edmonds Shoe Company, of Milwaukee, and has so consistently studied Dr. Munson’s book, entitled “The Soldier's Foot and the Military Shoe,” ‘ that he has no trouble at all in convincing the merchants that his shoe is best for the civilian as well as for the soldier. “We claim that the Edmonds U. S. Army shoe,” says Mr. Jennings, “is the real Liberty Shoe, asrit enables the merchant to fit the greatest number of civilian feet. Our factory is as well systematized as the Ford factory, and all unnecessary red tape and selling expense has been eliminated. Our idea is so unique in the shoe industry, and one which means such low costs of production,

“ARMY SHOE” JENNINGS

that merchants are ordering in quantities as high as 10,000 pairs. The trouble is that they all want their shoes for immediate delivery.”

Sept.21,1918

Boot and shoe recorder v. 73 (Aug.-Sept. 1918).

“TURNING OUT” SHOES

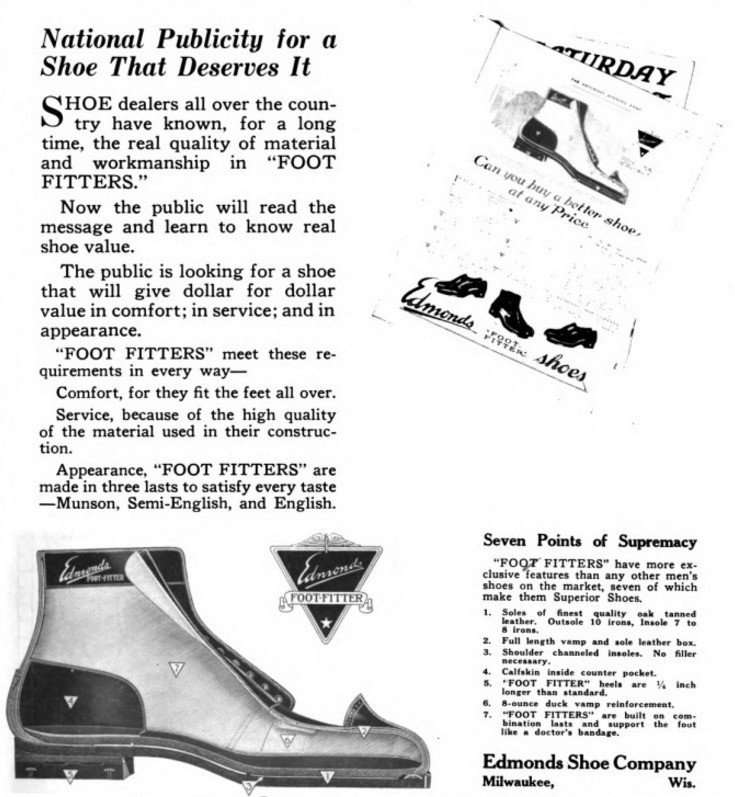

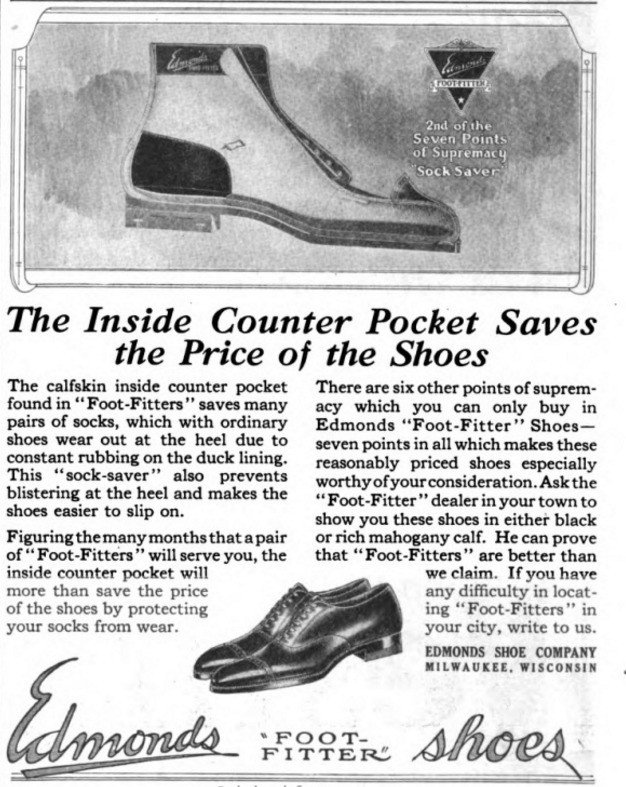

The Army Last and Leathers for Civilian Use W. A. Edmonds of the Edmonds Shoe Company, Milwaukee, WIS., conceived the idea that if an automobile factory, making but one'type of automobile, could turn out more automobiles at a lower price to the consumer, the same idea could be adapted to the shoe business. Mr. Edmonds backed his convictions with his experience as a manufacturer and with his money and went to it. For the basis of his “Flivver,” he selected the Munsonlast, and for the body a good, durable tan calfskin of soft tannage, a good looking, good wearing, G. W. Service Shoe. He equipped his plant to make three hundred pairs per day. It wasn’t long till the orders were coming so strong that more machinery was bought, additions were made and the output doubled. Orders have been on the increase until recently the daily production reached one thousand pairs. Here is concentration to the limit. No change of patterns, no shifting of machinery, no switching of workmen from one thing to another. Every employee doing the same thing all the time certainly makes for rapidity and efficicncy. One last, one grade of upper, one grade outsolc, one grade insole, one grade workmanship——just one show: Goodyear welt Army shoe on Munson last and that shoe Milwaukee quality. The phenomenal growth of this factory which started without a dollar’s worth of business on its books last June and now making a thousand pairs :1 day, shows the idea of conccntrzition in a shoe factory to be well founded.

Oct. 5, 1918

Boot and shoe recorder v. 74 (Oct.-Nov. 1918).

The Edmonds Shoe Company thoroughly inspect every pair of shoes before shipment. Automobile and truck manufacturers send their trucks on test runs before they O. K. same for shipment and the above shoe company is as particular in the inspection of every pair of shoes which bears its trademark. It has lately secured the services of Mr. Chas. Frank, who will inspect each pair of Edmonds' U. S. Army Shoes before packing. Mr. Frank for many years has been connected with leading manufacturers of shoes, retailing as high as $12.00 per pair. He will not only see to it that each and every pair of shoes is COMMERCIALLY PERFECT before treeing and finishing, but he will see to it that the treeing and finishing are as carefully done as though our shoes were marked at the highest wholesale price. The right shoe of every pair meeting Mr. Frank's O.K. will hold an inspector's slip, reading as follows: “This pair of U. S. Army Shoes made over the famous Dr. Munson's U. S. Army Last, is guaranteed to be commercially perfect and to contain heavy oak soles, whole grain lift solid leather heels, grain sole leather inner soles, steel shanks, grain leather inside counter pockets and heel stays, fast color eyelets, high grade durable linings, inside grain leather vamp reinforcements, full length outside heel stays, full length vamps.—“Made in the Factory of a Single Shoe.’”

Oct. 12, 1918

Edmonds’ Force 100 Per Cent

The Edmonds Shoe Co., Burleigh and Weil Streets, Milwaukee, is now floating over its factory its 100 per cent hanner, indicating that every worker in every department subscribed to a Liberty Bond of the fourth issue. This is a record of which the company and its employes are very proud, and one which few industries of Milwaukee have been able to equal.

Dec. 14, 1918

Boot and shoe recorder v. 74 (Dec. 1918-Jan. 1919).

From Repair Man to Shoe Merchant

When Mr. Goldfarb installed his shoe repairing equipment, little did he dream that one day his business would so develop that he would become a retail shoe merchant. Nevertheless, this was accomplished. Mr. Goldfarb selected justthe right environment for his business and the war was an additional factor in developing it. This store and repair shop is located near a cantonment at Des Moines, Iowa. In writing to the “Recorder" Mr. Goldfarb says, “We were the first store from the Camp Dodge Interburban Station and practically 95 per cent of the oificers and men passed our Soldiers Are Returning to Civilian Life store. We soon conceived the idea of becoming exclusively military merchants and for months averaged one thousand

sales each week. “We carry several lines of Army shoes in our store but our strongest feature is the Edmonds U. S. Army shoe. We soon afterwards opened another store at Camp Dodge where we did an excellent business on more Army shoes. “We found that the fact that a soldier was furnished a field shoe and must wear it when he went on liberty made him a ready customer for the Garrison Shoe built on the Munson last.

“We also feel that now that the war is over many men in the military line will continue to observe the same trend of style." There is an old adage, "Be Johnny on the spot." There is always an opportunity for the live, wide-awake repair man to expand his business, whether it be a further development of the repair and findings department or a complete transition from shoe repairing to shoe selling.

Dec. 28, 1918

1919

Edmonds Output Growing

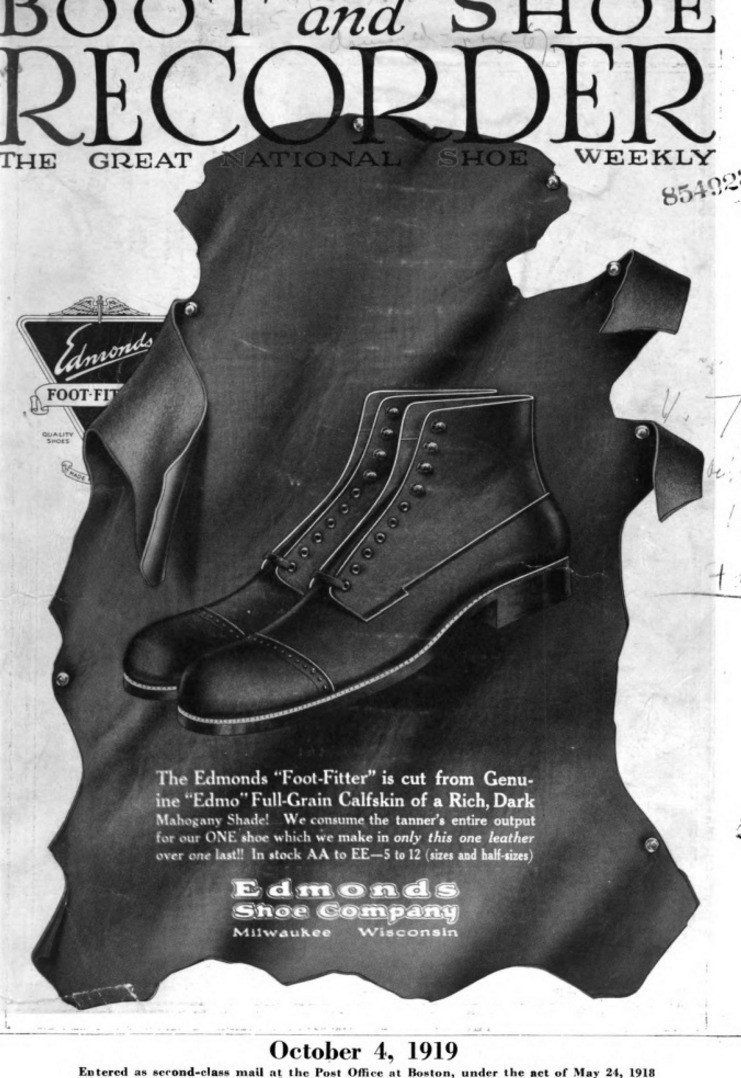

The Edmonds Shoe Company, Milwaukee, will increase its capacity to 1,500 pairs a day on March 1, making another record in the history of this rapidly growing concern. The Edmonds Shoe Company makes only one shoe, in oneleather, over one last, and as such is unique in the shoe industry. The factory commenced operations in July last year with an output of 300 pairs a day. In August this was raised to 600 pairs; in September to 800; in November to 1,000, and about a month ago to 1,200 pairs. The factory uses the entire output of one tannery, devoted exclusively to the production of a full, fine-grain calfskin of a rich, dark mahogany shade, of straight chrome tannage. The last has been improved in various ways from the regulation Army design to make it even more desirable for civilian wear.

Feb. 8, 1919

More Edmonds Progress

The Edmonds Shoe Co., Weil and Bnrleigh Streets, one of the youngest and fastest growing shoe manufacturing concerns in Milwaukee, has given further evidence of its progress by the announcement that its capital stock has been increased from $100,000 to $350,000. Although the company less than a month ago increased its output from 1200 to 1500 pairs daily, arrangements already are being made for another large increase; so that by June 15 or July 1, the daily output will be at least 2,000 pairs. Orders are being placed for more machinery and other equipment, the complete installation of which will require about three months.

March 15, 1919

The Edmonds Shoe Co., Milwaukee, is installing new machines and otherwise enlarging its facilities to bring its output up to 2,000 pairs a day by May 15 or June 1. The capacity was increased to 1,500 pairs only two months ago. This company which started in business last July, is making but one shoe in one leather over one last. Orders already received for immediate as well as future delivery, more than justify the above mentioned increase of 500 pair per day. This shoe is based on the standard Munson last and several improvements have recently been made in the pattern. The Edmonds “Foot-Fitter" which is made of genuine “Edmo" calfskin of a dark, rich mahogany shade is now made with top facings. hooks and tongue. This shoe is Munson in forepart and combination in waist, instep and heel. Numerous other factories are considering details of enlargement but are not yet ready to divulge plans.

March 22, 1919

The A. H. Berry Shoe Company, Portland, Me., have been appointed exclusive New England distributors for the Edmonds “Foot Fitter." This shoe is made by the Edmonds Shoe Co. of Milwaukee, Wis.. who make only this one style of shoe in one leather and over one last. This company, which started in business last July, has been enjoying a rapidly increasing business in New England. The uBoot and Shoe Recorder" takes pleasure in congratulating both parties in this affiliation.

March 29, 1919

Boot and shoe recorder v. 74-75 (Feb.-Mar. 1919)

Boot and shoe recorder v. 74-75 (Feb.-Mar. 1919).

The “Recorder" has received a letter from Thomas R. Allen, who styles himself “The Man with the One Shoe." Mr. Allen is salesman for the Edmonds Shoe Company, Milwaukee, Wis., in North and South Carolina exclusively. He writes to the “Recorder" as follows: “My business in North and SouthCarolina in the last four months is something immense. Those who have Travels for Edmonds Shoe Co. The Edmonds' Foot Fitter in stock are very much pleased with the shoe and are placing large orders for immediate and Fall delivery. It is a great seller. “When it comes to selling, no other ‘Shoe can hold a candle to Edmonds' Foot Fitter. lt is one of the greatest business men's shoes on the market ‘today. I do not miss a city or small ‘town. Everywhere I go merchants buy Without an argument. "The Edmonds' dark, rich mahogany-Shade in the new Foot Fitter makes it a splendid looking shoe."

April 12, 1919

Boot and shoe recorder v. 75 (Apr.-May 1919).

An example of the pressing nature of the demand for Milwaukee quality shoes is found in the shipment of a full carload by fast express by the Edmonds Shoe Company to a New York merchant who needed the 7,500,or more pairs of “Foot-Fitters" in a hurry to supply the enormous demand from sailors and soldiers returning to American shores from foreign lands. This particular merchant is located near the wharves where nearly all of the American transports discharge their human cargoes and he has been so overwhelmed for goods that for weeks he had telegraphed and telephoned for more shoes, with the result that an entire express car full was dispatched to him on the Twentieth Century Limited out of Chicago last Saturday. Probably no other American shoe factory has ever‘ made so unique and novel a delivery, which has been heralded far and wide in the trade as a sample of the service that goes with the now famous slogan of local shoe industries—“Quality First —All Ways—Milwaukee."

April 5, 1919

“Going to Meet the Boys"

The Edmonds Shoe Company of Milwaukee, Wisconsin, made what is believed to be one of the most novel shipments of shoes. The car contained more than 7,500 pairs f Edmonds' shoes. The car was inscribed, “Going to Meet the Boys," was attached to he Pennsylvania Ltd. train at Chicago and rushed to the East. The New York shoe merchant who bought the carload of goods on a rush order is situated near the wharf where thousands of American soldiers are landing from Europe. Army and Navy men make a bee-line for a shoe store as soon as they reach America, so as to discard heir heavy Army shoes. The New York merchant found the Edmonds Shoe popular and the express car of “Foot Fitters" met his demands for a prompt delivery.

April 19, 1919

Boot and shoe recorder v. 75 (June-July 1919).

A RECORD IN SHOEMAKING

Edmonds Shoe Company Has 2,400 Pairs Daily Capacity Although the Edmonds Shoe Company, Milwaukee's youngest shoe manufacturing concern, made its first shipment last July, it is now averaging 2,400 pairs of just one shoe per day. This Company is the only concern in the world making just one shoe in just one leather over just one last, and it is probably on account of this fact that some doubted the accomplishment of such a feat. In less than twelve months, the “Foot- Fitter" plant has increased its average daily output on just one shoe from nothing to 2,400 pairs per day. During this period, over 14,000 accounts have been placed on the books of the Company and now that these merchants are all beginning to mail-order in a large way, it is apparent that the present daily output of 2,400 pairs will soon be substantially increased. Plans are already being prepared for another factory which will also have a daily output of 2,400 pairs.

June 28, 1919

Delivery Trim By Aeroplane

Cleveland Shoe Merchant Presents a Novel Display We are showing herewith a photographic reproduction of a special window trim of “Foot-Fitters” as delivered via aeroplane by the Edmonds Shoe Company of Milwaukee, Wis., to the Stone Shoe

July 19, 1919

Employees’ Profit-Sharing System

An Investment Plan for Shoe Factory Workers Guaranteeing Ten Per Cent on Stock Earnings—-Interest Compounded Quarterly THE Edmonds Shoe Company of Milwaukee has put into operation a plan whereby its shoe factory employes may participate in the earnings of the company. This concern offers its employes a liberal proposition to become stockholders. It is possible for all employes to avail themselves of the opportunity, as the company arranges weekly payments which are agreeable to the employe. The stock ofl'ered is the regular 7 per cent preferred stock of the company, with an additional 3 per cent, making a total of 10 per cent on the employes’ investment. The 10 per cent earnings are compounded quarterly. The Edmonds Shoe Company issues a 100 per cent preferred stock certificate as soon as $100 has been paid in. The employe who deposits $5 per week for a period of twenty years would actually invest $5,200, but would have $16,595.46 to his credit, because to his original deposits would be added the interest compounded quarterly, amounting to $11,395.46. The employe who deposits $10 per week will in twenty years have paid in $10,400, but this principal will cause interest.

Sept. 20, 1919

Commercial Mission

To Visit the United States in Goodrich, Daniel Green Felt Shoe the Fall Company, P. Cogan & Son and in ' C. H_ BABER The Chamber of Commerce of 1919 he annexed the accounts of the United States announces that B. A. Corbin Shoe Company and the Edmonds Shoe invitations extended by the Chamber to Great Britain, Company of Milwaukee. France, Italy and Belgium for a joint, commercial Mr. Baber sees large possibilities for American trade mission to visit the United States have been accepted.

Aug. 2, 1919

Shipment to Paris

That the call for Milwaukee-made shoes for export is opening up in splen did shape is evidenced by the fact that the Edmonds Shoe Company has just made a shipment of 3,000 pairs of "Foot-Fitters" to a Paris shoe merchant. ‘This order of 3,000 pairs, which was shipped complete from stock within forty-eight hours after its receipt at the factory, was, in fact, a re-order on an original order of 61-8 pairs which was shipped in February.

Aug. 2, 1919

Boot and shoe recorder v. 75-76 (Aug.-Sept. 1919).

Boot and shoe recorder v. 75-76 (Aug.-Sept. 1919).

FACTORIES EXPANDING

Growth of Importance of the Shoe Industry Cause of Growth The immediate expansion which is made necessary by the relatively enormous demand for Milwaukee-made shoes is well illustrated by the establishment of numerous new industries and the enlargement of the existing ones. One of the largest of the plant extension projects will be that of the Edmonds Shoe Company, which in a little over a year has become one of the most conspicuous successes in the shoe industry

Aug. 23, 1919

Boot and shoe recorder v. 76 (Oct.-Nov. 1919).

Boot and shoe recorder v. 76 (Oct.-Nov. 1919).

BIG “FOOT-FITTER” PLANT

Being Erected by the Edmonds Shoe Company, Capacity 3,000 Pairs That Milwaukee is rapidly growing in importance as a shoe market is evidenced by the new shoe plants recently completed and now in course of erection. The newest and one of the most novel shoe plants now under course of construction is that of the Edmonds Shoe Company, which is being erected at Bremen, Concordia and Weil Streets. The unit now being erected will have a daily capacity of three thousand pairs and will also house the general ollices as well as the stock-rooms and general supply departments. Immediately on completion of the first unit, a sister unit with an additional capacity of 6,000 pairs will be erected. Construction work will be completed by January 1, 1920. The building will cover a very large single floor area. The dimensions will be 4-77 feet in length and 134- feet in width. The building will be of steel skeleton construction and the walls will be composed of tapestry brick with terra cotta cornice and cut stone trimmings. A modern steam heating (vacuum) system is to be installed.

Oct. 18, 1919

Daily Output 2,400 Pairs

Just 15 months have passed since the Edmonds Shoe Company put into operation the unorthodox idea of making just one shoe in one leather over one last. That this idea is a practical one is demonstrated by the fact that in this short time this company has increased in average daily output from nothing to 2,400 pairs per day, and the demand for its product is increasing to such an extent that the 3,000 pair daily output of the first unit, is already nearly sold up for the coming Spring season.

Oct. 18, 1919

SHOE MARKET GROWING

A Program of Development in Shoe Manufacturing

The following shoe manufacturing concerns will soon be producing three distinct specialty lines of footwear: James-Buntrock Shoe Company (children's stitch-down shoes on nature lasts); Jocelyn Shoe Company, 2218 Clybourn Street (women's fine shoes); Rohn & Ryan Shoe Company (men's fine shoes in calf, kid and side leathers). Among the factories and additions under way should be mentioned the Ludington factory of the F. Mayer Boot & Shoe Company, as well as the V. Schoenecker Boot & Shoe Company’s addition to their Milwaukee plant. The Nunn, Bush & Weldon Shoe Company are erecting a 3,000-pair factory at Fond du Lac and have already started a four-story addition to their Milwaukee plant. The Weyenberg Shoe Manufacturing Company have just completed a new plant at Beaver Dam and are at this time also completing a plant at Portage, Wisconsin. The steel work has already been started on the mammoth one-shoe plant of the Edmonds Shoe Company.

Oct. 25, 1919

EDMONDS SHOE COMPANY

New Factory Expected Ready for Occupancy

The Edmonds Shoe Company, Milwaukee, is making good progress in the erection of its new "Foot-Fitter" plant, despite the handicaps resulting from a spell of extremely low temperatures and heavy snowfalls in the last week or two. It is confidently hoped that the new factory will be ready for occupancy during the first ten days of January.

Dec. 20, 1919

Boot and shoe recorder v. 76 (Dec. 1919-Jan. 1920).

1920

Boot and shoe recorder v. 76 (Dec. 1919-Jan. 1920).

Boot and shoe recorder v. 76 (Feb.-Mar. 1920).

Boot and shoe recorder v. 76 (Feb.-Mar. 1920).

Edmonds Shoe Company

At the booth of the Edmonds Shoe Company, the live-wire sales manager, C. A. Dickens, boosted Milwaukee for the 1921 Convention as well as the Edmonds line. The president of the company, W. A. Edmonds, was also at the booth, as well as A. . Baldwin, Texas representative, and H. E. Stine, California representative. At the exhibit, the complete Edmonds line of one shoe, in one leather, over one last, was shown——one pair each on all seven sizes, 5 to 12%, and half sizes, AA to EE. A shoe is being produced now on a triple A last. “We shall begin moving into our new factory on January 31," said Mr. Dickens, and will move one department at a time at night, so as not to lose any time. Our new factory will have a capacity of 3,000 pairs a day on one shoe. The boys are now starting on the road with the coming season's lines."

Jan. 17 , 1920

The new "Foot-Fitter" Plant Feb. 14, 1920

Three large and representative boot and shoe industries enlarged their capitalization in the last few days. The Edmonds Shoe Company, which has just completed its new plant, raised the amount of capital from $350,000 to $1,000,000, making it truly a “big leaguer” of the Quality First Market.

Feb. 28, 1920

INCREASE OF CAPITALIZATION

By the Edmonds Shoe Company to $1,000,000

The Edmonds Shoe Company has increased its capitalization from $350,000 to $1,000,000, which is equally divided among common and preferred stock. The $500,000 worth of common stock is already taken, and although the preferred stock is not being handled by outside parties, more than half is already subscribed for. This stock is sold very rapidly on account of its unusual features, which Milwaukee business men regard as an exceptional opportunity. The Edmonds Workers' Improvement Association of the Edmonds Shoe Company has for the past five months been publishing a weekly factory paper known as the “Edmonds Workers' Review.” This eight-page weekly, which is liberally illustrated, is edited and prepared for the printers by a large staff of editors and reporters working under the direct supervision of the officers and councilmen of the Improvement Association. Edmonds Workers made merry at the “FOOT-FITTER” Festival, as held in the new one-shoe plant in the evening of February 13. This big house-warming event, which was attended by all Edmonds Workers and a few immediate friends, was quite similar to olden style events of this character.

March 6, 1920

A PEDO-PEPTOMIST La Coste Evans Is “Foot Fitter” Ambassador to S. Carolina La Coste Evans is exclusive “Foot Fitter” Ambassador to the people of the Palmetto State. - Mr. Evans is a “Pedo-Peptomist,” born at charming Cheraw, South Carolina – a seller and fitter of shoes for 33 years. Mr. Evans writes: “I have been with the Edmonds Shoe Company of “Quality First Town” only two weeks and their leading salesmen all have the “dry grins and shivers” when they think of the Evans' weekly quota dozens being chalked up on the sales manager's blackboard. “Shoely”—“The Foot Fitter Route.”

March 20, 1920

Boot and shoe recorder v. 77 (Mar. 27-May 29, 1920).

Boot and shoe recorder v. 77 (Mar. 27-May 29, 1920).

Boot and shoe recorder v. 77 (June-July 1920).

Boot and shoe recorder v. 77 (June-July 1920).

Boot and shoe recorder versus 77 from 78 (August - September 1920).

Boot and shoe recorder versus 77 from 78 (August - September 1920).

Price Correction On the front cover of the July 31 issue of the “Boot and Shoe Recorder" the Edmonds “Foot-Fitter" was quoted at $7.55. This was an error—the correct price is $7.85. and has been in effect since April 15, 1920. This price of $7.85 is guaranteed to December 31,1920

Aug. 14, 1920

Edmonds Shoe Company

the production of it. We will not obtain the right kind of golden eggs by killing the goose that laid them. Unionized under buyiug means compulsory under-production which does not mean lower prices at wholesale. ' 7 4 "None of my customers have so far been able to convince me that it is possible to further reduce prices at wholesale by forcing the tanners and shoe factories to reduce their outputs. Those people who shout the loudest about lower prices say that there should be no reduction in wages. These people are insisting that the product of labor, however, should be sold at a still lower price. If the object of newspaper propaganda has been to stop the‘profit of tanneries and shoe factories, their movement has been a great success. When the inducement of a reasonable profit is taken away from the manufacturer, scarcity is bound to occur sooner or later.”

1920 November 6

1921

Boot and shoe recorder pair 80 (October - November 1921).

Boot and shoe recorder pair 80 (October - November 1921).

Boot and shoe recorder V. 80 (January 1922 from December 1921).

WA Edmonds, shoes Co., Ltd. of Edmonds, of Milwaukee, Wis., President, recently, was a visitor in the Boston market. Mr. Edmonds, his factory reports that are making about 3000 pairs of weal of men per day.

December 3, 1921

1922

Joseph Ceviak With Edmonds

Joseph Ceviak will sell Edmonds Foot Fitters in Chicago and nearby territory. Mr. Ceviak has for some time represented Harsch & Chapline in this territory. He is well acquainted with the trade. In his opinion the outlook for business in men’s medium high grade shoes is quite good. Merchants are pretty

JOSEPH CEVIAK

Who travels Chicago and nearby territory for Edmonds Shoe 00. well cleaned up and are playing close to lines that can be sized up quickly.

January 7, 1922

Boot and shoe recorder pair 80 from 81 (month - March 1922).

Boot and shoe recorder pair 80 from 81 (month - March 1922).

Boot and shoe recorder versus 81 (July from June to 1922).

Boot and shoe recorder versus 81 (July from June to 1922).

Boot and shoe recorder versus 81 (July from June to 1922).

boot and shoe recorder versus 81 (August - September 1922).

Boot and shoe recorder v. 81-82 (Aug.-Sept. 1922).

boot and shoe recorder versus 81 (August - September 1922).

boot and shoe recorder versus 81 (August - September 1922).

Boot and shoe recorder versus 82 (October - Novem ber 1922).

Boot and shoe recorder versus 82 (October - November 1922).

The Saturday evening post. v.195 1922 Oct-Dec.

The Saturday evening post. v.195 1922 Oct-Dec.

The Saturday evening post. v.194:no.45-48 (1922).

The Saturday evening post. v.195 1922 Oct-De

SILVER CREEK NY NEWS 1922 - 0030.pdf

Fredonia NY Censor 1921 Nov-1922 Nov Grayscale - 0294.pdf

Richmond KY Daily Register 1922-05-09_5.pdf

Fredonia NY Censor 1921 Nov-1922 Nov Grayscale - 0441.pdf

Medina NY Tribune 1919-1923 Grayscale - 1061.pdf

Hartford KY Republican 1922-04-07_4.pdf

Three Oaks MI Acorn 1920-1922 - 1415.pdf

Duluth MN Evening Herald 1922 (1484).pdf

Victor NY Herald 1923 - 0061.pdf

1927?

Fredonia NY Censor 1926 May-1927 May Grayscale - 0738.pdf

Fredonia NY Censor 1926 May-1927 May Grayscale - 0647.pdf

世界中の靴の歴史を研究をしています。ご協力いただければ嬉しいです。よろしくお願いいたします。