QFP (Quad Flat Package)

Quad Flat Pack (QFP) is an integrated circuit (IC) packaging technology that plays an important role in the field of IC packaging. QFP is a surface mount package that is widely used in the IC industry, especially in applications requiring relatively large pin counts, such as consumer electronics, communication equipment, and industrial control systems.

Although QFP is a relatively mature packaging technology, it is still innovating in order to cater to the increasing needs of modern electronic devices for size, performance and cost. These innovations drive the continuous evolution of QFP technology and bring more possibilities to the entire integrated circuit industry to meet changing market demands. Today, we’re going to talk about it in depth and go a little further into it.

What is a Quad Flat Package

A Quad Flat Package (QFP) is a type of surface-mounted integrated circuit (IC) package that features distinctive "gull wing" leads extending from each of its four sides. This packaging design enhances the ease of soldering and facilitates surface mounting on printed circuit boards (PCBs). Unlike traditional through-hole mounting, QFP is not designed for socketing, making direct soldering onto the PCB the standard method of attachment.

QFPs are characterized by a variety of specifications, including the number of pins and the pitch between these pins. The pins are the electrical connections that link the IC to the external circuitry on the PCB. QFPs come in a range of pin counts, commonly ranging from 32 to 304 pins, catering to a wide spectrum of applications with varying degrees of complexity. The pitch, or the distance between adjacent pins, typically falls within the range of 0.4 to 1.0 mm, allowing for flexibility in design and accommodating different requirements for miniaturization.

The "gull wing" leads, shaped like the wings of a seagull, provide mechanical support and ensure a secure connection during the soldering process. This design allows for a compact footprint on the PCB, making QFPs suitable for applications where space efficiency is crucial.

QFP Package Sizes

Example of QFP Package Sizes

QFP (Quad Flat Package) comes in a variety of sizes to meet the diverse needs of integrated circuits (ICs) in different applications. The thickness, pin count, lead pitch, and overall dimensions play crucial roles in determining the suitability of a QFP for a specific electronic device.

Regular QFP Thickness

Traditional or regular QFPs typically exhibit thicknesses ranging from 2.0 to 3.8 mm. This thickness provides a balance between structural integrity and the need for a compact profile. The larger the package size (measured in pins), the thicker the QFP tends to be, as it needs to accommodate a greater number of leads and provide sufficient space for the integrated circuit.

Thin Quad Flat Package (TQFP)

Thickness Range: TQFP packages are designed with a reduced thickness compared to regular QFPs. They offer a slimmer profile, which is advantageous in applications where space constraints are critical.

Example Sizes:

A TQFP package with 32 pins might have a lead pitch of 0.8 mm, with overall dimensions of 5 mm by 5 mm and a thickness of 1 mm.

For a larger TQFP with 256 pins, the package might measure 28 mm by 28 mm, have a thickness of 1.4 mm, and feature a finer lead pitch of 0.4 mm. This finer pitch allows for a higher pin density, making it suitable for more complex ICs.

Lead Pitch and Pin Count

The lead pitch refers to the distance between the centers of adjacent pins. Smaller lead pitches are associated with higher pin densities, allowing for more connections in a given area. As mentioned, regular QFPs and TQFPs can have lead pitches ranging from 0.4 to 1.0 mm, depending on the specific requirements of the IC and the application.

QFP package sizes vary to accommodate a spectrum of applications, from compact and thin TQFPs suitable for space-constrained devices to regular QFPs with larger dimensions for more complex integrated circuits. Engineers and designers carefully evaluate these dimensions to choose the most suitable QFP for their specific electronic system requirements.

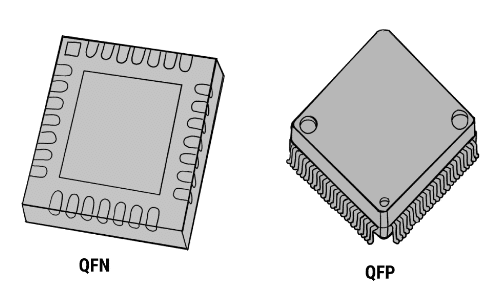

QFN vs. QFP Packaging: What are the Differences

Conclusion Table

In summary, the key differences between QFP (Quad Flat Package) and QFN (Quad Flat No-Lead) packaging lie in their lead configuration, size, number of pins, and lead pitch:

Lead Configuration

The key difference in lead configuration between Quad Flat Package (QFP) and Quad Flat No-Lead (QFN) packaging lies in how they connect to a printed circuit board (PCB). QFP has leads or pins extending from the sides and bottom, allowing for through-hole or surface mount connections. In contrast, QFN lacks leads on the sides, and its connections are made through pads on the bottom surface, using surface mount technology.

Size

Size is a notable contrast between Quad Flat Package (QFP) and Quad Flat No-Lead (QFN) packaging. QFP is typically larger because of the leads extending from its sides and bottom. These protruding leads allow for through-hole or surface mount connections but contribute to a larger physical footprint on the printed circuit board (PCB). On the other hand, QFN is generally smaller and more compact as it lacks protruding leads. The absence of these leads on the sides makes QFN well-suited for applications where space efficiency is crucial.

Number of Pins

The number of pins is a significant distinction between Quad Flat Package (QFP) and Quad Flat No-Lead (QFN) packaging. QFP can accommodate a higher number of pins, ranging from 32 to well over 100. This design makes QFP suitable for components demanding numerous connections, such as integrated circuits (ICs) in complex electronic systems. In contrast, QFN typically has fewer pins, usually less than 32. The reduced pin count aligns with applications where a lower number of connections is sufficient. QFN's design is well-suited for components with less intricate connectivity requirements, contributing to its use in various electronic devices where a compact form factor is essential.

Lead Pitch

Lead pitch, or the distance between adjacent leads, distinguishes Quad Flat Package (QFP) and Quad Flat No-Lead (QFN) packaging. QFP has a smaller lead pitch, enabling a higher pin density on the package and the PCB. In contrast, QFN generally has a larger lead pitch, resulting in a less dense pin configuration. This difference influences the overall size, complexity, and manufacturing considerations, guiding the choice between QFP and QFN based on specific application requirements.

In practical terms, QFP is often chosen for components demanding a high pin count and a larger physical footprint on the PCB, such as microcontrollers in industrial applications. On the other hand, QFN is favored for components with fewer connections and a need for space efficiency, common in applications like consumer electronics and miniaturized devices. The choice between QFP and QFN depends on the specific requirements of the electronic system and the desired balance between size, pin count, and assembly technology.

TQFP vs LQFP: What is the Difference

Conclusion Table

Thin Quad Flat Package (TQFP) and Low Profile Quad Flat Package (LQFP) are variations of the Quad Flat Package (QFP), each with specific design characteristics.

Thickness

As the name suggests, TQFP is characterized by a reduced thickness compared to standard QFP. This design is aimed at providing a thinner profile, making it suitable for applications with stringent space constraints.

LQFP, on the other hand, emphasizes a lower overall height while maintaining a similar thickness to standard QFP. The emphasis is on reducing the package's height rather than making it significantly thinner.

Applications

TQFP is often chosen for applications where minimizing the overall thickness of the device is crucial. This makes it suitable for slim-profile electronic devices and systems with limited vertical space.

LQFP is designed to address applications where a lower overall package height is a priority, but not necessarily a significant reduction in thickness. It is well-suited for devices where vertical space is constrained, and a flatter profile is desired.

Package Size

TQFP, like standard QFP, comes in various sizes and pin counts, but the emphasis is on providing a thinner form factor.

LQFP maintains a similar size to standard QFP but with a lower overall profile.

Lead Configuration and Pitch

Both TQFP and LQFP typically have gull-wing leads that facilitate surface mounting on a PCB. The lead pitch (distance between adjacent leads) can vary based on the specific design and requirements.

While TQFP focuses on reducing overall thickness for applications with strict space constraints, LQFP aims to maintain a similar thickness to standard QFP while emphasizing a lower overall package height.

Different Types of QFP

Quad Flat Package (QFP) comes in various types and variations to meet specific design requirements.

Standard QFP

This is the traditional Quad Flat Package with pins extending from all four sides.

Thin QFP (TQFP)

TQFP is designed with a reduced thickness compared to standard QFP. It is suitable for applications where minimizing the overall thickness of the device is crucial.

Very Thin QFP (VQFP)

VQFP takes the concept of reduced thickness further than TQFP. It is an even thinner variant designed for applications requiring an extremely slim profile.

Low-Profile QFP (LQFP)

LQFP emphasizes a lower overall height while maintaining a similar thickness to standard QFP. It is suitable for applications where reducing the package's height is a priority, but not necessarily making it significantly thinner.

Plastic Quad Flat Package (PQFP)

PQFP is a type of QFP where the package material is plastic. This is in contrast to ceramic QFP, which uses ceramic as the package material.

Ceramic Quad Flat Package (CQFP)

CQFP utilizes ceramic as the package material. Ceramic packages offer better thermal performance compared to plastic, making them suitable for applications where heat dissipation is a critical factor.

Enhanced Quad Flat Package (eQFP)

eQFP is a term sometimes used to refer to QFP packages that incorporate enhancements or specific features beyond the standard configuration. These enhancements could include better thermal management, improved electrical performance, or other specialized characteristics.

Plastic Leaded Chip Carrier (PLCC)

While not strictly a QFP, PLCC is a related package type with a similar flat shape. It has leads that extend from all four sides, but they are arranged differently than in QFP.

The spacing of pins on a QFP can vary, as you mentioned, ranging from 0.4mm to 1mm apart. The specific type of QFP selected depends on factors such as space constraints, thermal considerations, and other requirements of the application.

Function of QFP

The Quad Flat Package (QFP) serves as a crucial component in the world of integrated circuits, offering a protective enclosure for ICs while establishing high-density electrical connections between the IC and the printed circuit board (PCB). Designed for surface mount technology (SMT), QFP's flat profile and numerous gull-wing leads enable efficient and automated assembly processes, contributing to space efficiency on the PCB. With its versatility, heat dissipation capabilities, and adaptability to various electronic applications, QFP has become a widely adopted packaging solution for integrated circuits requiring a significant number of interconnections within electronic circuits.

More Videos

この記事が気に入ったらサポートをしてみませんか?